Home »

Misc »

How to build a lifetime basketball hoop

How to build a lifetime basketball hoop

What NOT to Do When Assembling a Lifetime Basketball Hoop

A few months ago I forewarned you of the top three things to know before assembling a Lifetime Basketball Hoop. Today, I'm going to share with you some of the specific hurdles I alluded to in that post that we crossed along the way when assembling our own Lifetime Basketball Hoop (model 90228). To be honest, I'm kind of embarrassed to share my story with you given some of the pretty major "oopsies" we had. After all, since I work for Lifetime, you'd think I'd know how to assemble the products. Not necessarily true. This was my first time assembling a Lifetime Basketball Hoop. Let's just say, I can definitely empathize with our customers now!

Before we started assembling, we laid out all of our parts and pieces to make sure we could easily find everything. Thankfully, all the parts and bags of hardware are labeled well. Simply read what part you need in the directions, look at the parts list in the front of the instruction manual to see what bag the part is in, and find the matching hardware bag.![]()

The first few steps seemed pretty easy. Then, we came to the step of putting the poles together (section 1.5). Since I work for Lifetime and hear from a lot of customers, I knew this is one of steps that is most often done incorrectly. If you jam the poles together too soon, they will be stuck together incorrectly and you are unable to separate them. (If this happens to you, please call the Lifetime Customer Care department!) But, if you follow the instructions, there are little warning signs in the corner of the pages that try to highlight areas that may be challenging and require attention to detail. So, we took our time and - ta-da - poles were assembled with no problems.

Oops #1

But then we got to section 2.2 - inserting the axle through the wheel, through the pole, and through the other wheel. Directions say, "Then have one adult position the Bottom Pole (ALE) within the Base as shown with the lip at the bottom of the pole facing outward." Key word: Lip. For some reason, we thought lip simply meant "edge" of the pole. But, look carefully at the bottom of the pole! One side has a curved edge that almost looks like it's dented - this is the lip! Make sure that lip faces away from the base! (You'll find out why that's important really soon, I promise. Read on…)

For some reason, we thought lip simply meant "edge" of the pole. But, look carefully at the bottom of the pole! One side has a curved edge that almost looks like it's dented - this is the lip! Make sure that lip faces away from the base! (You'll find out why that's important really soon, I promise. Read on…)

Oops #2

During section 2.3 we attached the pole braces to the base - backwards. Sigh. Not a huge deal, because we quickly noticed when we tried to attach the braces to the pole and the hardware wouldn't fit through the holes. Tip: Look at the picture closely to really figure out which end of the pole brace goes where.

We made it to section 3 in exactly one hour. Yay!

Oops #3

So, it turns out section 5.2 was our nemesis in more ways than one. First, we were supposed to bend the end of the Cotter Pin after we inserted it into the Clevis Pin. (Sounds more like medical surgery than basketball assembly, huh?) The diagram is a little confusing to really understand what it should look like finished, so I took a picture to hopefully make it a little easier for you. But, that was minor compared to the next hiccup…if you can even call it that. A round pole is round…it has no front or back. Right? Wrong! Unfortunately, we didn't notice that we put the pole on the base backwards (like I mentioned in Oops #2) until this section 5.2. when it was time to attach the adjustment mechanism to the pole. Hmmm, that's odd... our adjustment mechanism is on the front of the pole instead of the back of the pole like it should be. (Insert several big screams, throwing of tools etc.) Yes, we painstakingly took off the backboard, removed the wheels and pole, and reassembled it all correctly. It took every ounce of muscle and patience we had, but it was possible. Not easy, not quick, but possible.

But, that was minor compared to the next hiccup…if you can even call it that. A round pole is round…it has no front or back. Right? Wrong! Unfortunately, we didn't notice that we put the pole on the base backwards (like I mentioned in Oops #2) until this section 5.2. when it was time to attach the adjustment mechanism to the pole. Hmmm, that's odd... our adjustment mechanism is on the front of the pole instead of the back of the pole like it should be. (Insert several big screams, throwing of tools etc.) Yes, we painstakingly took off the backboard, removed the wheels and pole, and reassembled it all correctly. It took every ounce of muscle and patience we had, but it was possible. Not easy, not quick, but possible.

Fast forward one hour… now we were back on track.

The rest of the assembly was easy to understand, just awkward to accomplish at times. Awkward because once you have the backboard on the pole, you lay the system forward and have one adult hold it while you finish attaching the adjustment mechanism arms. We were hesitant to put any weight on the rim until the system was assembled but my arms were getting tired from holding the heavy system! So, we ended up using a sawhorse to help me support the weight of the system. It's not in the manual, but it worked nonetheless. The next morning, we let our kiddos climb up on the step ladder and help with the last final step... hanging the net!

We were hesitant to put any weight on the rim until the system was assembled but my arms were getting tired from holding the heavy system! So, we ended up using a sawhorse to help me support the weight of the system. It's not in the manual, but it worked nonetheless. The next morning, we let our kiddos climb up on the step ladder and help with the last final step... hanging the net!

We really did try to make a video to document our assembly and help you. However, because we ended up having to reassemble so many steps, I fear it would just be more confusing than helpful. We'll see, maybe I'll get motivated to edit it someday. In the meantime, hopefully these few words of wisdom, er caution, will help. In all, with our one hour redo, it took us four hours to assemble. So, hopefully, you'll have less do-overs than us and finish in about three hours.

Now that's it's been several months since we assembled our basketball hoop, the assembly headaches are long gone. They've since been replaced with fun family memories of playing H-O-R-S-E and Around the World with our kids and neighbor kids.

PORTABLE BASKETBALL HOOP ASSEMBLY - Prime Spaces Assembly Services

-

PORTABLE BASKETBALL HOOPS WE ASSEMBLE

Most portable basketball hoops we assemble fall into categories below:

- Polycarbonate portable basketball hoop assembly

- Acrylic portable basketball hoop assembly

- Tempered glass portable basketball hoop assembly

- Youth portable basketball hoop assembly

-

RETAILERS WE ASSEMBLE

We often assemble portable basketball hoops from popular brands such as:

We have experience assembling portable basketball hoops from brands such as:

- Lifetime

- Spalding

- Silverback

- Giantex

- SKLZ

- and many others!

Many of these brands utilize varying amounts of hardware and have their own unique designs for their portable basketball hoops. Our technicians are true experts and have the capability to properly build any portable basketball hoop that you choose.

Our technicians are true experts and have the capability to properly build any portable basketball hoop that you choose.

-

ASSEMBLY COST

For Greater Boston cities inside the I-95 belt the cost of assembling different portable basketball hoops will vary depending on the number of parts and hardware, clarity of the instruction manual, and backboard size and material.

- Polycarbonate backboard portable hoop assembly typically ranges between $95-110.

- Acrylic backboard portable hoop assembly typically ranges between $120-135.

- Glass backboard portable hoop assembly typically ranges between $145-225.

-

COST FACTORS

Amount of hardware and parts included – Although many portable basketball hoops look similar to one another, they all don’t arrive in the same condition when shipped. One brand may send you bigger, pre-assembled parts, while another brand may send you individual smaller pieces along with the hardware for you to build out larger parts ultimately into a fully assembled portable basketball hoop. Generally speaking, the more hardware included means the more assembly the manufacturer left for us to complete.

Generally speaking, the more hardware included means the more assembly the manufacturer left for us to complete.

Clarity of the instruction manual – Before sending you a quote we research your portable basketball hoop’s assembly manual. Some manuals do a great job of dividing up the steps into easy to interpret illustrations, while others may include multiple steps in one single illustration which requires more time to analyze and interpret the manual. A well-illustrated instruction manual can be the difference between spending an hour or less assembling a portable basketball hoop versus two or more hours of assembly with an instruction manual that is imprecise.

Size and material of the backboard – Portable basketball hoop backboards can range in size from 44-inches all the way up to 60 inches. Polycarbonate backboards are the cheapest and most common types found in households. Acrylic backboards are considered mid-tier and are a heavier material than polycarbonate. Tempered glass provides the best quality and is the heaviest of the three materials. Regardless of the material, they all must be handled with skill and extreme caution to avoid injury and damage to property or the hoop. Individual pieces can be heavy and take time to safely unbox and organize prior to assembly.

Tempered glass provides the best quality and is the heaviest of the three materials. Regardless of the material, they all must be handled with skill and extreme caution to avoid injury and damage to property or the hoop. Individual pieces can be heavy and take time to safely unbox and organize prior to assembly.

-

ASSEMBLY DURATION

Portable basketball hoop assemblies typically range between 2-5 hours. Unboxing and organizing each of the individual parts prior to assembly will take between 15-25 minutes depending on the type of portable basketball hoop being assembled.

-

SERVICE AREAS

We serve the cities in the counties listed below. If you have a portable basketball hoop that needs assembly outside our service area please contact us to see if we can arrange to travel to your location.

Suffolk County: Boston, Chelsea, Winthrop, Revere

Norfolk County: Avon, Braintree, Brookline, Canton, Dedham, Milton, Needham, Norwood, Quincy, Randolph, Sharon, Stoughton, Wellesley, Westwood, Weymouth

Middlesex County: Arlington, Belmont, Cambridge, Everett, Malden, Medford, Melrose, Newton, Somerville, Stoneham, Watertown, Waltham, Weston, Winchester, Woburn

Making a basketball hoop with my own hands Roman Volkov, low-rise country blog

The word "leisure" is usually viewed from different angles and for some it is associated with a sofa, armchair and TV, but for some it means active rest. The second option is ideal for residents of country houses and cottage owners, but I'm not talking about physical labor here, such as planting or harvesting potatoes, but about sports. The fact is that on your own land plot you can always build a basketball hoop with your own hands, and concrete a small playground near it, for example, for 4-6 people. Of course, you will have to sacrifice a piece of the garden, but, as M. Zhvanetsky said: “Only its treatment can be more expensive than health.”

The second option is ideal for residents of country houses and cottage owners, but I'm not talking about physical labor here, such as planting or harvesting potatoes, but about sports. The fact is that on your own land plot you can always build a basketball hoop with your own hands, and concrete a small playground near it, for example, for 4-6 people. Of course, you will have to sacrifice a piece of the garden, but, as M. Zhvanetsky said: “Only its treatment can be more expensive than health.”

Basketball backboard and hoop

As you understand, in addition to the hoop, you will also have to make a basketball backboard with your own hands, without which the whole game and even a simple hit lose their appeal. Therefore, for a complete assembly of this type of sports equipment, we will consider how and from what materials such a design can be given life. Of course, for an American or even a European from a rich country, such an article will be incomprehensible - for them it is a waste of time and, if necessary, they simply pay the bill for the inventory and its installation. But in our situation, it all looks different, so the question of how to make a basketball hoop with your own hands remains relevant to this day.

But in our situation, it all looks different, so the question of how to make a basketball hoop with your own hands remains relevant to this day.

What you need to make a shield

First of all, I want to say that when making a basketball backboard with your own hands, you should adhere to the geometric parameters provided for by FIBA (International Basketball Association). At a minimum, this will allow you to fully enjoy throwing the ball from any position from different distances - experienced athletes often send the ball to a certain point of the shield so that it hits the ring when it ricochets. Of course, in words, all this sounds very simple, which cannot be said about the practical work in creating such structures.

The fact is that some people simply put together a backboard and a basketball hoop for children with their own hands from inexpensive pine boards and wire, but even for a child this construction will be too unreliable in terms of strength. Nobody argues that a pine board is a good building material, but, firstly, it belongs to soft wood species, and, secondly, it will collapse under the influence of precipitation and temperature changes (you won’t install such inventory in the house, unless, of course, it is a country villa). To save money, you can still use a planed pine board, but at the same time it must be treated with an antiseptic to protect it from decay. But the front side of the shield will have to be sewn up with monolithic polycarbonate - in this case, the surface will turn out to be perfectly flat.

Nobody argues that a pine board is a good building material, but, firstly, it belongs to soft wood species, and, secondly, it will collapse under the influence of precipitation and temperature changes (you won’t install such inventory in the house, unless, of course, it is a country villa). To save money, you can still use a planed pine board, but at the same time it must be treated with an antiseptic to protect it from decay. But the front side of the shield will have to be sewn up with monolithic polycarbonate - in this case, the surface will turn out to be perfectly flat.

Now more specifically about the size of the basketball hoop with your own hands. Whatever material you make the backboard from, in any case, you should adhere to the dimensions approved by the International Basketball Association (FIBA). So, you should get its area with parameters 1830x1070 mm, and the outer diameter of the ring - 460 mm. Everyone remembers the rectangle drawn above the ring, which so often facilitates the process of throwing the ball into the basket - the rectangle should have 610x460 mm. The distance between the ring and the playground also has a fixed parameter and is 3050 mm, while the shield itself from the floor should be located at a height of 2750 mm.

The distance between the ring and the playground also has a fixed parameter and is 3050 mm, while the shield itself from the floor should be located at a height of 2750 mm.

In terms of materials, as mentioned above, DIY basketball backboards are best made from inch boards of hardwood that are available in your area, such as Canadian maple, ash, oak, beech, rowan, etc. .d. Of course, the mass of such a design will turn out to be much larger than that of a pine shield, but given that it will only have to be mounted once plus a long service life, it is better not to use soft wood. Due to the fact that the basketball shield will always be in the open air and exposed to atmospheric precipitation, it must be treated with an antiseptic before painting - such protection reliably helps against fungal mold, as well as various small bugs and larvae.

In my opinion, the best material for a homemade basketball backboard for the outdoors is oriented strand board, also known as OSB or OSB (orient strand board). But the fact is that all these boards differ in class, corresponding strength and moisture resistance:

But the fact is that all these boards differ in class, corresponding strength and moisture resistance:

- OSB-1 is mainly used for furniture frames and internal partitions in the building. The plate has low strength and low moisture resistance.

- OSB-2 is intended for internal work, most often, these are rigid structures of a bearing type. The plate has high strength and low moisture resistance.

- OSB-3, this is just the material that is almost perfect for a basketball backboard on the street. The plate has high strength and high moisture resistance.

- OSB-4 is needed for bearing structures with heavy loads, such as foundations and even runways. The plate has super high strength and high moisture resistance.

Moisture-resistant plywood type FK or FSF is also suitable for sawing out a basketball backboard, but it is desirable that it be laminated. In terms of thickness, both for plywood and for oriented strand board, a parameter of 15 mm is enough - it will freely hold the ball hits. In addition, plywood and OSB-3 do not need to be treated with an antiseptic, as this is a glued material where factory bactericidal impregnation is present.

In addition, plywood and OSB-3 do not need to be treated with an antiseptic, as this is a glued material where factory bactericidal impregnation is present.

Important information! I noticed that some people recommend using chipboard or MDF for a basketball backboard, but I will say right away that such “advisers” simply never worked with such materials. Both chipboard and MDF are designed exclusively for indoor use in dry-type rooms.

Ring

Of course, the ring can be made independently from smooth steel reinforcement using a pipe bender or simply find a cylinder of the required diameter, although, to be honest, I have not seen such, but this does not mean that they do not exist. Be that as it may, you will need a bar with a section of 12-14 mm and metal plates for welding mounting brackets or a channel. Such manufacturing always has its own significant disadvantages: it is very difficult to bend an ideal circle and there will be no fasteners for the basket on the ring, besides, all this takes a lot of time. It is much easier to simply buy such a ring in a sporting goods store - it is not so expensive. But FIBA standards are observed there, and there are brackets in the kit - you can fix it in just 5-10 minutes.

It is much easier to simply buy such a ring in a sporting goods store - it is not so expensive. But FIBA standards are observed there, and there are brackets in the kit - you can fix it in just 5-10 minutes.

Recommendation: fastening the ring to the shield is best done using bolted connections with washers, since fixing with self-tapping screws in this case will be short-lived.

Basketball stand

A handmade basketball post is usually made of steel pipe or a square profile with a cross section of at least 60 mm. I do not recommend fixing the shield directly to the stand to avoid the possibility of collision with a vertical support during the game. At the top, you will need to make an ejection of at least half a meter and install a spacer in the form of a scarf. The triangle is the most rigid geometric figure, so sagging of the shield under the influence of its own mass or the passage of time is excluded here. From the bottom side, the triangle will also not be superfluous, but it is desirable to weld two horizontal crossbars there. Both the lintels and the triangle will be under the concrete layer in the foundation. To fix the shield to the rack, it is best to install a harness from a 50x50 mm corner around its perimeter and fasten the gander extending from the rack to it using bolts or welding.

Both the lintels and the triangle will be under the concrete layer in the foundation. To fix the shield to the rack, it is best to install a harness from a 50x50 mm corner around its perimeter and fasten the gander extending from the rack to it using bolts or welding.

Basketball backboard painting

For some reason, everyone on the web says that the shield should be painted white, but I don’t see the point in this, at least for two reasons. Firstly, the white color glares in the sun, which is not very pleasant for the players and, secondly, it is a very easily soiled color, and it is not very convenient to wipe such a panel at a height. It is best to stop at green or blue with a red or brown frame around the ring and around the perimeter. To do this, first cover the shield with glyphthalium primer (GF) on both sides, and when it dries, apply two or three layers of pentaphthalium paint (PF) of the desired color.

When all coats of paint are dry, mark with a pencil around the perimeter and above the ring with a line width of 50 mm. As I said, the drawn rectangles are best done in red or brown - they are clearly visible on a blue or green background, but black varnish is also suitable for this purpose. The central rectangle from the lower edge of the shield should be located directly below the ring and this parameter is easy to calculate. So, if the ring should be at a height of 3050 mm, and the backboard at a height of 2750 mm relative to the playing area, then the distance from the bottom edge to the central rectangle should be 3050-2750 = 300 mm - everything is very simple.

As I said, the drawn rectangles are best done in red or brown - they are clearly visible on a blue or green background, but black varnish is also suitable for this purpose. The central rectangle from the lower edge of the shield should be located directly below the ring and this parameter is easy to calculate. So, if the ring should be at a height of 3050 mm, and the backboard at a height of 2750 mm relative to the playing area, then the distance from the bottom edge to the central rectangle should be 3050-2750 = 300 mm - everything is very simple.

Masking tape of any width should be used to make the stripes clear and beautiful. Glue the tape along the line left by the pencil, and paint over the gap. Just do not rush to remove the adhesive tape immediately after painting - so the PF can spread and your efforts will not be justified - remove the tape only after 2-3 hours.

Stand foundation

A small foundation is required to install a single tube stand under a basketball backboard. Perhaps, with the word “single-pipe”, some readers will associate with a hole that is made by hand or a power drill, but, alas, these are misleading sensations. The thing is that a horizontal profile is welded to the bottom of the vertical support and the support is fastened to the jumper with some kind of profile for rigidity (in the form of a triangle). This precaution prevents the shield from tilting towards the site over time. In addition, one or two crossbars are welded on this branch so that the rack cannot lean to the left or right. Therefore, to fill the foundation, you will need not drilling, but an ordinary trench, and if it is deeper than 40 cm, then it is more convenient to make it in a stepped way.

Perhaps, with the word “single-pipe”, some readers will associate with a hole that is made by hand or a power drill, but, alas, these are misleading sensations. The thing is that a horizontal profile is welded to the bottom of the vertical support and the support is fastened to the jumper with some kind of profile for rigidity (in the form of a triangle). This precaution prevents the shield from tilting towards the site over time. In addition, one or two crossbars are welded on this branch so that the rack cannot lean to the left or right. Therefore, to fill the foundation, you will need not drilling, but an ordinary trench, and if it is deeper than 40 cm, then it is more convenient to make it in a stepped way.

For example, if the gooseneck is 50 cm long and the crossbars are 15 cm, then the length of the trench should be 60 cm and a minimum width of 25 cm. This is done so that all the metal is filled with concrete and does not come into contact with the ground (real protection against corrosion). If the trench is buried, then it is inconvenient to dig it along the edges, so one or two steps are made on one side to make it easier to pull out the soil. After digging is completed, a sand-gravel pillow 5-6 cm high is poured to the bottom (the larger the crushed stone fraction, the thicker the pillow is).

If the trench is buried, then it is inconvenient to dig it along the edges, so one or two steps are made on one side to make it easier to pull out the soil. After digging is completed, a sand-gravel pillow 5-6 cm high is poured to the bottom (the larger the crushed stone fraction, the thicker the pillow is).

A layer of concrete 4-5 cm high must be poured on top and a stand for the shield should be installed on it. It is leveled vertically with a level or plumb line, and then concreted flush with the ground. To ensure that no air bubbles remain in the solution, it should be compacted with an electric or pneumatic vibrator. If you do not have such a tool available, use a shovel handle to compact the mixture - this is also very effective. Until the concrete has completely hardened (three weeks), it is better not to throw the ball into the ring, since such vibrations can cause cracks in the foundation.

Conclusion

I didn't talk about creating a playground, as this is a topic for a full-fledged article. Nevertheless, I want to mention that if you have the opportunity to asphalt, then use it - asphalt is quite plastic and tolerates temperature changes well. But if you are going to concrete such a field, during or after pouring it will need to be divided into sections of no more than 2 m2 - this will avoid cracking. The carving during pouring is done by installing inserts, and the hardened concrete is simply cut with a grinder.

Nevertheless, I want to mention that if you have the opportunity to asphalt, then use it - asphalt is quite plastic and tolerates temperature changes well. But if you are going to concrete such a field, during or after pouring it will need to be divided into sections of no more than 2 m2 - this will avoid cracking. The carving during pouring is done by installing inserts, and the hardened concrete is simply cut with a grinder.

Do-it-yourself basketball backboard with height adjustment (20 photos). Basketball backboard dimensions and markings

Today we will talk about how to make a high-quality basketball backboard and basketball net with your own hands at home from improvised materials. We will also consider the technology of manufacturing a basketball backboard and a net for playing basketball for children or adults.

In order to make a simple DIY basketball hoop for kids, we need thick wire and rope. Instead of thick wire, you can take an old unused hula hoop, cut it, shorten it and reconnect it. It is important to leave a "sprout" for attaching the ring to the shield.

It is important to leave a "sprout" for attaching the ring to the shield.

If you want to make a basketball hoop with your own hands from thick wire, then in order to get the most even circle, we recommend using a cylindrical fixture designed to serve as a template. We wind the wire around it. And do not forget to leave a "sprout" for attaching the resulting ring to the basketball backboard.

The diameter of the metal blank for the ring should be slightly larger than the diameter of the basketball. Then you should take the prepared rope and cut it into 20-22 identical segments. At the same time, the length of each should be 2.5 - 3 times greater than the planned length of the mesh hanging.

These pieces are attached to the metal ring at regular intervals. You need to tie the ropes exactly in the middle so that 2 ends of equal length remain free. Then we connect in turn 2 ends of nearby ropes around the entire circumference of the ring. This is the first level of our grid. Then, similarly, we tie the ropes to the next level, etc.

Then, similarly, we tie the ropes to the next level, etc.

If you want to make a basketball hoop for your home, you can tie the bottom of the net so that the ball stays inside when it hits. This will help reduce the chance of an accidental bounce of the sports equipment after hitting the basket.

DIY basketball backboard for adults. How to make a professional basketball backboard - here you have to try. How to make a basketball backboard at home. The process of making a basketball backboard is no more difficult than making sports predictions, especially if the necessary materials are available.

Here is a typical instruction for making a basketball backboard at home. For the base of the basketball backboard, you can choose a sheet of plywood, which is inexpensive and not hard to get either. A sturdy rectangular piece of plexiglass or thick plastic may also work well.

If the basketball backboard will be installed outdoors, then it is worth choosing the material for its base based on considerations not only of strength, but also of resistance to adverse weather conditions.

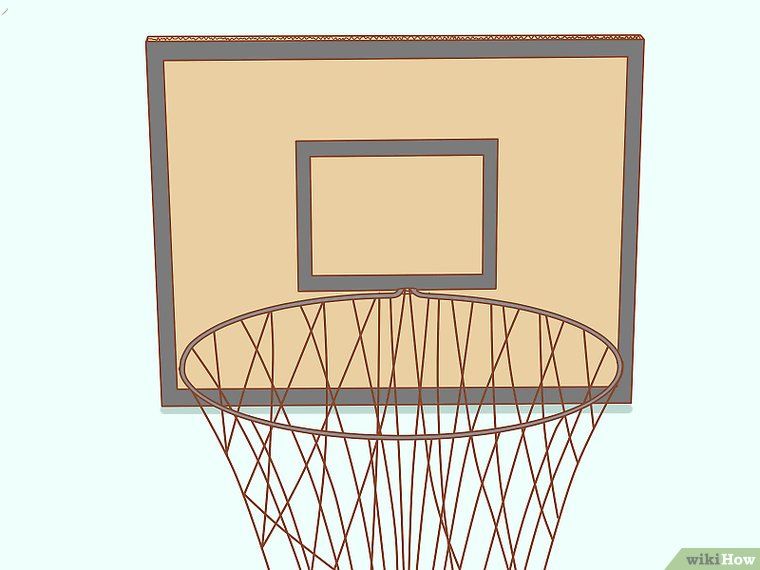

The next step is to choose a place where the basketball backboard will be attached. When choosing such a place, the main thing to remember is that the lower edge of the shield should be at a height of 290 centimeters from the ground, and the ring should be located at a height of 305 centimeters.

Now you need to mark and cut out the dimensions of the plywood blank. The ideal size of a standard basketball backboard are the following parameters: width - 1.8 meters, height - 1.05 meters. This size will allow players to make more accurate and varied throws.

Before you start cutting out the workpiece, you need to use a pencil to outline the dimensions and draw lines along which the workpiece will be cut. It is better to cut it with a jigsaw, when working with which you must be careful.

After the blank of the future basketball backboard is ready, it will be necessary to draw a white square on it, which plays a very important role.

The white square is a kind of guide for the players when shooting, with the help of such markings it is much easier to get the ball into the basket. If the ball is correctly thrown into the corner of this square, then it will definitely reach the goal.

If the ball is correctly thrown into the corner of this square, then it will definitely reach the goal.

In order to mark out such a square, not only a brush and paint are needed, but also knowledge of the dimensions of the rectangle. Its external dimensions are 59 centimeters horizontally and 45 centimeters vertically.

When marking out, it should also be taken into account that the upper edge of the base of this rectangle must coincide with the level of the upper plane of the ring. The width of the stripes of the square should be 5 centimeters.

Basketball hoops

Material - solid steel, inner diameter 45 cm and painted orange.

The metal bar of the ring must have a minimum diameter of 16 mm and a maximum diameter of 20 mm. On the bottom of the ring there must be devices for attaching nets, such as to prevent injury to the fingers. The mesh must be attached to the ring at twelve equally spaced points along the entire perimeter of the ring. Net attachment devices must not have sharp edges or crevices that could get caught by the player's fingers.

The ring is attached to the structure supporting the basket so that no force applied to the ring is transmitted directly to the backboard. Therefore, there should be no direct contact between the ring and the device that secures the ring to the shield and the shield. However, the gap must be small enough that fingers cannot get into it.

The top edge of each ring must be placed horizontally at a height of 3.05 m above the ground at an equal distance from the vertical edges of the backboard.

The nearest point on the inside of the ring must be 15 cm from the face of the shield. You can use rings with a shock absorber.

Made of white cord and designed to hold the ball momentarily as it passes through the basket. The net length must be at least 40 cm and not more than 45 cm.

Each net must have 12 loops to attach to the ring.

The top sections of the net must be sufficiently rigid to prevent:

Net entanglement on the ring and possible entanglement.

Ball stuck in the net or thrown out of the net by the net. Basketball net can be woven from braid, twine, rope, thick threads. The braid or thread is first cut into segments.

The length of each segment must be four times the length of the grid. The number of segments is determined as follows: the ring intended for the grid is measured, and the resulting value is divided by four. The do-it-yourself basketball backboard is almost ready. Now it needs to be firmly fixed. To do this, you will need 4 large bolts that can withstand a load of 30 kg, and drill four holes in the wall or any other place where the basketball backboard will be mounted.

Use a spirit level to drill holes evenly. After that, you can start installing the shield. It is very inconvenient to do it yourself, so you should again resort to the help of friends who can insure you on the stairs, as well as file and hold the shield.

Once the bolts are installed and screwed into place, the basket can be hung up so that you can finally play on the court with a new basketball backboard that will last for many years.

In short, you can make a good basketball backboard with your own hands. But it is important to pay attention to one serious point.

The fact is that no matter how it seems to us from the side that the contact of the ball and the basket hoop is quite soft, it should be noted that the impact load on the fastening of the hoop to the backboard is very high. The weight of the ball (if you do not go into the definition of physical values) during contact with the ring increases many times, even when thrown from an average distance.

Well, with an inaccurate hit from a long distance, this blow can reach destructive power. And such a load acts on the mount hundreds and thousands of times. So that your work does not go to waste, that is, the future ring with a shield is a reliable design, you need to pay maximum attention to attaching the ring to the shield and then the same shield to the wall or other structure. Regarding the material of the shield, it can be put together from the same inexpensive pine boards available, and preferably from harder wood. Proposals to make a basketball backboard from plywood, fiberboard, plastic do not stand up to criticism. The first two positions do not pass due to the fact that if your shield hangs in the season in the rain and the sun, nothing will remain of it.

Proposals to make a basketball backboard from plywood, fiberboard, plastic do not stand up to criticism. The first two positions do not pass due to the fact that if your shield hangs in the season in the rain and the sun, nothing will remain of it.

Plastic will naturally withstand all of these weather conditions, but is unlikely to be affordable. Plastic plastic is different, because the one that is used in the gym is very expensive, another different lottery ... will stand it - will not stand it. But a wooden board, it is a material that has stood the test of time and history. It is known that the official dimensions of the basketball backboard are as follows - a width of 1 meter 80 centimeters and a height of 1 meter 5 centimeters.

But in principle, you can try to build a flat square of boards 3 cm thick and 80 cm x 80 cm in size, I think this area will be quite enough to play normally or work out the throw. Basically, only a square is actively used when throwing (its dimensions are 59centimeters, height 45 centimeters) above the hoop, since this is the small square you need to be able to hit if you want to perform a throw from the shield.

Then (if it hits this square), the ball will most likely fall into the ring. Even in this case, if you perform a throw with a rebound from the shield, the load on the shield itself will be very small, but on the fastening of the shield and the ring, in this case, the pressure will be maximum.

Basketball hoop is made from a metal rod with a diameter of 16 - 20 millimeters. I think everyone understands that in order to protect against atmospheric precipitation, the entire structure should be painted with the appropriate paint, which can be bought at the store, explaining to the seller why the paint is needed.

As a result, I will repeat myself and say that when trying to make a basketball backboard on your own, pay attention to the fastening of the ring to the backboard. This is the most fragile place in this design.

In this article you will learn:

- What are the dimensions of the backboard with hoop

- How to make a basketball hoop with your own hands

- Where to buy a ready-made basketball backboard with a ring

Basketball-like games were found among the ancient Scandinavian peoples and Mexican Indians. Today in northern Mexico, one of these games is popular - "Pok-Ta-Pok". It is believed that it appeared due to religious rites, which eventually turned into sports fun and an attraction for tourists. How the game "basketball" appeared, and what is a basketball backboard with a ring as a necessary element of this popular game, we will learn in this article.

Today in northern Mexico, one of these games is popular - "Pok-Ta-Pok". It is believed that it appeared due to religious rites, which eventually turned into sports fun and an attraction for tourists. How the game "basketball" appeared, and what is a basketball backboard with a ring as a necessary element of this popular game, we will learn in this article.

When basketball and the first backboard with a hoop appeared

The forerunner of basketball is the 19th-century children's game "duck on the rock", familiar to the Canadian inventor of basketball, James Naismith. The principle of the game was to hit a small stone on top of a large one.

The concept of basketball was finally formed when D. Naismith moved to the USA and became a physical education teacher at the Youth Christian Organization College (YMCA) in Springfield, Massachusetts. Already teaching physical education and as a college professor, he faced the challenge of creating a winter game between baseball and football. Naismith, given the weather conditions this time of year in Massachusetts, decided that this game should be played indoors.

Naismith, given the weather conditions this time of year in Massachusetts, decided that this game should be played indoors.

Naismith's goal was to create an outdoor game for the students of the Christian Workers' School that required more than just strength and dexterity. It was supposed to develop coordination of movements in teenagers and at the same time be interesting.

So, in the winter of 1891, under the leadership of Naismith, the first basketball baskets were installed in the college gym. Baskets from under the fruit, fixed on both sides of the hall on the balconies, which encircled the room around the perimeter, acted as basketball hoops. Such baskets were fastened at a height of 3.05 m, it was this indicator that became the international standard, which is observed to this day.

The task of the players was to throw the ball (at that time they used football) into the basket. The first basketball match was held in the same hall on December 21, 1891. According to the conditions of the game proposed by Naismith, each team had 9 people, which exactly coincided with the number of students in the group.

The news of the new game quickly spread throughout America, and Naismith was asked to send the rules. On February 12, 1892, after learning the rules and mastering the basics of technology, the students of Springfield College played the first "official" match in the history of basketball, which ended in a 2-2 draw.

This meeting turned out to be so successful, and the rumor about a new type of competition spread so quickly that soon two Springfield teams began to hold demonstration competitions, which were already attended by hundreds of spectators. The initiative was picked up by students from other educational institutions, and the following year, the Northeast of America was swept by a real basketball fever.

The rules of basketball that Naismith wrote himself as a college instructor at 1891 year, was a list of 13 points, which eventually formed the basis of modern international rules, which hardly fit on 200 pages. In 1893, instead of baskets, they put iron rings with a grid, two years later they added shields, and two years later the team was reduced to 5 people.

What is a basketball backboard with a ring today? The shield is made of a transparent material, usually a single piece of tempered impact-resistant glass with a degree of hardness corresponding to that of a 30 mm thick hardwood shield. It is allowed to produce such shields from other materials, but in this case they must be painted white and comply with other requirements for such sports equipment.

The front side of the shield is made smooth, a marking line is applied along the edges, a rectangle measuring 45 cm vertically and 59 cm horizontally is indicated at the place where the ring is attached. Moreover, the upper edge of the base of the rectangle must coincide with the level of the upper plane of the ring. White outlines are applied to transparent shields, and black is used in other cases. The width of the lines is 5 cm.

The basketball backboard with hoop is installed at right angles on both sides of the playing court, parallel to the front lines. The center of the front surface of each shield lies on perpendicular lines reconstructed from points located on the site at a distance of 120 cm from the middle of the inner edge of each front line.

The center of the front surface of each shield lies on perpendicular lines reconstructed from points located on the site at a distance of 120 cm from the middle of the inner edge of each front line.

Shields are upholstered, the following requirements apply to it:

- the sides of the boards and the bottom end are covered with soft material at a height of at least 35 cm from the bottom corners;

- the lower end is upholstered with material at least 5 cm thick;

- the rear and front surfaces of the shield should be decorated with upholstery material, the thickness of which is at least 2 cm, at a height of at least 2 cm from the bottom end.

The following requirements are imposed on the structures on which the shields are attached: their front parts, including upholstery, are placed at a distance of at least two meters from the outer edge of the front line. They are painted in bright colors that contrast with the walls of the sports hall in order to provide sufficient visibility to the players of both teams.

The structure on which the backboard with the hoop is mounted is fixed to the floor of the court in such a way as to prevent it from moving during the game.

Structures used for fastening shields must be upholstered with soft material behind the shield at a distance of 120 cm from the front surface of the shield. The minimum thickness of the upholstery is 5 cm, and the density is the same as that of the upholstery of the shields.

The base of the structure from the side of the playground is upholstered with dense soft material to a height of at least 215 cm, the thickness of the upholstery is 10 cm.

The minimum value of the so-called "indentation factor" of the upholstery of panels and structures is 50%. This figure means that when an appropriate force is applied to the upholstery, its indentation should be within 50% of its original thickness. The upholstery material provides protection to players from possible injuries during the game.

Basketball backboard and hoop dimensions

It's hard to imagine a basketball court without a basketball backboard and hoop. For them, world standards established by the International Basketball Federation have been adopted.

For them, world standards established by the International Basketball Federation have been adopted.

A basketball backboard is a rectangular or square panel to which a hoop is attached. Mounting is provided on the shield for mounting on a pole or hanging on a wall: rigid mounting is required, the product should not stagger and move.

Shield dimensions - 1.8x1.05 meters, with an installation height of 2.9 meters. By NBA standards, the size of the backboard must be 72x42 inches. Two shields are installed opposite each other from different ends of the field, the material is impact-resistant (as an option, tempered glass, acrylic, wood). Lines are drawn on a smooth surface. Models of basketball backboards with a net that are not intended for stationary installation are equipped with the same mounting elements as in the brackets for hanging punching bags. This method makes basketball backboards able to withstand a lot of weight and securely fixes them.

Ring or basket includes a metal (steel) circle covered with netting without a bottom. It is installed at a height of 3.05 meters from the floor and indented 15 cm from the lower edge of the shield. The inner diameter is selected from the range of 45–45.7 cm. The basketball hoop is painted in a bright color, usually orange. It is impossible to allow the transfer of load from the basket to the shield, therefore, the installation of the product is carried out with special attention.

It is installed at a height of 3.05 meters from the floor and indented 15 cm from the lower edge of the shield. The inner diameter is selected from the range of 45–45.7 cm. The basketball hoop is painted in a bright color, usually orange. It is impossible to allow the transfer of load from the basket to the shield, therefore, the installation of the product is carried out with special attention.

DIY basketball hoop

Homemade basketball hoops are installed in summer cottages or hung in the yard near the house. In the summer, you can throw the ball with pleasure, feeling like Michael Jordan for a moment. This game is available to everyone: both children and adults. The benefits of such a seemingly simple exercise are incredible!

Have you set out to make your own basketball hoop and don't know where to start? Further, we will talk about this.

To make your own basketball hoop, you need thick wire and rope. Instead of a wire, an old unnecessary sports hoop is suitable, which is cut, shortened and connected again. Do not forget to leave a "sprout" for attaching to the shield.

Do not forget to leave a "sprout" for attaching to the shield.

Making a thick wire basketball hoop requires some trickery. To obtain an even circle, a cylindrical fixture can be used as a template on which the wire is wound. But, before cutting off the wire, do not forget about the "sprout" for attaching to the wall.

The diameter of the metal blank for the hoop is slightly larger than the diameter of a basketball. Next, the pre-prepared rope is cut into 20–22 identical segments. The length of each is 2.5–3 times the planned length of the net hanging.

These segments are attached to the metal ring at regular intervals. The ropes are tied in the middle, and the two ends of equal length are left free. Then the two ends of the nearby ropes are tied in turn, and so on along the entire circumference of the ring. It turns out the first level of the grid. The ropes of the next level are tied in the same way, and so on.

When making a basketball hoop for the home, the bottom of the net can be tied, which will allow the ball that hits the net to stay inside. Thus, the ball does not accidentally bounce to the side.

Thus, the ball does not accidentally bounce to the side.

Now we know how to make our own basketball hoop. But it is necessary to answer the question, which is better - a home-made or a quality product bought in a store?

Making your own parts is fun. To do this, you only need free time, the necessary materials and a third-class welder. If you do not have this, then it is better to purchase a basketball hoop with a backboard from trusted manufacturers.

In order to make a basketball backboard with fastening, you will need six meters of a 2x2 cm profile pipe, 8.5 m of a 2x4 cm profile pipe, a backboard made of laminated moisture-resistant plywood, a basketball hoop, six anchor bolts for attaching to the wall. The design is assembled from three parts for easy wall mounting.

The desired part is cut off from the shield.

Metal structures are welded and the prepared AKZ is applied to them.

The shield is drawn, pasted over with adhesive tape, and lines 5 cm wide are applied to it.

Attach the shield to the frame.

Where to buy a basketball hoop with a backboard

In such an active game as basketball, every little thing is important! Even at the finish line, troubles happen: the ball is in the ring, but gets tangled in the net and gets stuck. This moment is ruined! How to avoid such troubles?

The following requirements apply to the ring net:

- 12 fastening loops;

- length should be 40–45 cm;

- use rigid white cord as material;

- The upper is made in such a way as to prevent throwing the net on the ring, tangling or sticking the ball.

How to choose the right basketball net? The main thing to pay attention to is the material, diameter and thickness of the thread, type.

- Capron and nylon products are used more often. The latter is more wear-resistant, so for professional training, boron falls on this material.

- The diameter is selected according to the diameter of the ring and the ball.

- For professional basketball nets, thick threads of increased strength are used, but for amateurs, more fragile ones can be used.

- Type: knotted and knotless. Products of the first type are widely used, but knotless basketball nets for the hoop look better and absorb the impact of the ball well, and are more reliable.

Looking for quality hoop backboards? We will help you make the right choice. Sportstyle started its activity in 1992 and has been successfully presenting its goods and services in the markets of Russia and neighboring countries for more than 20 years.

One of the main activities of the company is the production of sports equipment. Our products are very popular and in demand, among them:

- boxes, rings, bags and pears;

- wrestling mats;

- equipment for sports aerobics and much more.

The range of our company is not limited to sports equipment. We are happy to produce for you tents for summer cafes and weddings, awning garages, trade tents, awnings for cars and boats, as well as pool bowls.

Our son became interested in basketball in the summer, and although there is a beautiful stadium with a basketball court half a kilometer from home, sometimes you want to knock the ball near the house. Therefore, it was decided to make a do-it-yourself basketball backboard near the fence (so that you could knock on a relatively hard road surface, and the ball would fly away, if it didn’t hit the ring, to our site, and not to someone else’s.

We deviated a little from the standard and we got the following dimensions (photo is clickable)

The shield was cut out of OSB (just in case, two layers were twisted, and one more, a small square, was added to strengthen the fastening - this can be seen in the photo below) and carefully painted with oil paint

The support was made of metal profiles 50*50 and 56*56 in size.

The fact is that that part of the fence, at which the shield is attached, is supposed to be removable for us - it is there that we usually dump soil, crushed stone and other minerals. Therefore, it was decided to make the shield removable. Along with support. We implemented this idea like this.

Therefore, it was decided to make the shield removable. Along with support. We implemented this idea like this.

A short post driven into a previously dug hole and cemented. The long one is fixed in it with screws. If necessary, it can be taken out. Actually, this is also visible in the diagram above.

Just before the shield was built, we had a welding machine, and this product proved to be a great workout. The pipes were welded with the letter G, a beautiful rectangle was welded to a short crossbar, on which a shield was attached.

Mesh rings are sold for little money in all sports shops and in many hyper stores.

It turned out very nice.

Oh sport, you are the world!

There is nothing to do in the country, only bending metal, fumbling shish kebab, drinking beer.

It is necessary to go in for sports both by ourselves and by children.

True, for this you will first have to "bend the metal" and celebrate this matter with beer and barbecue.

Basketball backboard in the next series of the "Made of Metal" project.

Joint work of me and my father.

Batko studied the standards for the height and dimensions of a basketball backboard, made a wooden backboard, painted it, made wing screws, installed a pole. Well, in addition, he made critical remarks to the metal part.

I - designed the whole metal part and welded the metal.

Let's go!

01. First I sit down at the computer and sketch out the drawing of the shield and the pole itself.

The original plan was to put the ring in another place and pull it with a solid hitch to the nearest tree. But there turned out to be a lot of roots and they decided to put them in free flight and without a screed, because the ring in the upper part of the column remained rudimentary only in the drawing. Diagonals that are not in the drawing (green) have also been cancelled. We decided that the rigidity of the wooden shield and metal fasteners would be enough not to "walk".

Also on the move I changed the way of strengthening the outrigger knee. Not with a corner as in the drawing, but with two stripes on the sides, see the photo below.

A 5 cm profile was used for the pole, a 6 cm profile was used for the bracket strung on the pole. A strip is welded inside to prevent play.

All that adjoins the wooden shield is a 25 mm corner.

Important: the ring must be universal for both adults and children of different heights. Therefore, a height offset system was made.

02. The main large elements are welded: a pole, a knee, two stepson solid fuel boosters. The upper edge of the pillar and stepchildren is bevelled: for rainfall and for beauty.

03. More different types

04.

05. There is a strip welded inside the elbow pipe. At the top of the hole.

06. Welded shield fixing system. No, this is not a bottle of Zhatetsky Gus beer, this is gasoline.

07. Stepsons welded on. There was an error in the calculations. It was assumed that the stepchildren would strengthen the pillar from swinging, but they were attached lower than necessary. Further in the photo you will see that they protrude quite a bit from the ground. It would be possible to raise 30-40 cm higher. And now, nevertheless, the pillar sways during the game.

There was an error in the calculations. It was assumed that the stepchildren would strengthen the pillar from swinging, but they were attached lower than necessary. Further in the photo you will see that they protrude quite a bit from the ground. It would be possible to raise 30-40 cm higher. And now, nevertheless, the pillar sways during the game.

08. The heels are welded to the part that goes underground.

09.

10. Everything is painted

11.

12. Pit

13. It will be found so for a couple of days and you can continue the part of the pillar, because there was no putty for metal, to putty the seams. The putty was bought in addition, puttied and repainted a little later.

14. Up!

15. Shield assembly.

16. Done!

17. Now the ring is at its lowest height. Even lower than calculated, because one hole is not used (see the vacant thumb screw). Altitude change occurs with the help of one man-power on a stepladder.

18.

19. The village basketball open championship has begun!

Did you have to restrain yourself when you passed the basketball court in order not to throw the ball into the basket? Why hold back? Team sports reliably unite people of any age, religion and social status. And in order to look decent at any moment and on any site, it is enough just not to start training.

Small places for playing streetball can be equipped on sports grounds near the house, and rings can be built at summer cottages for children to play from improvised means. So, how to make a basketball hoop yourself?

Dimensions and materials required

- The inside diameter of the basketball hoop is 45 cm;

- the height of its upper edge above the playground is 3.05 m;

- ring material - metal bar, plastic pipe, improvised materials;

- diameter of a bar or pipe for a ring - 16-20 mm;

- distance from the ring to the shield - 15 cm;

- mesh length - 40-45 cm;

- mesh material - metal chain, synthetic cord, rope, braid.

Types of basketball hoops

Hoops can be different:

- metal with anti-vandal nets made of metal chain;

- metal with rope mesh;

- plastic with nets of various types of materials;

- creative (from the remains of construction, from old furniture, from large plastic containers).

The construction of a metal bar ring begins with marking. Since the basket must have an internal diameter of 45 cm, a rod or pipe is selected based on this.

Material length is calculated using the formula:

Bar length = Circle diameter x 3.14 (pi value). We have 45 × 3.14 = 141.3 cm.

Since we need to fasten the ring to the shield, let's take the length of the rod about 150 cm. You can bend the rod or pipe on a template (wheel), or you can bend it to size, measure the diameter and straighten it with a mallet. The rest of the rod or pipe should be prepared for fastening to the shield using drilled holes and screws.