How its made basketballs

How Are Basketballs Made? – branded.disruptsports.com

Have you ever wondered how basketballs are made? Basketball is a type of a rubber ball, similar to volleyballs and medicine balls. Of course, the basketball strikes a balance between these two, to be optimized for the fantastic sport of basketball. While the development materials have changed over time, the main design of the basketball didn’t change much. Read on further to learn more about the development and design processes of creating a basketball.

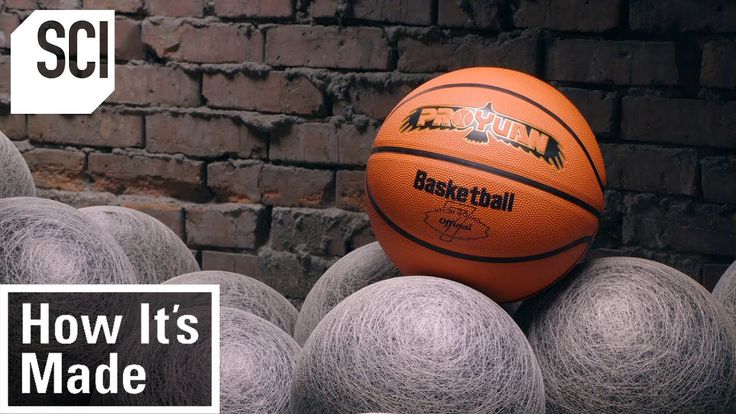

If you are in a hurry, check out this brief video that explains how are basketballs created:

https://www.youtube.com/watch?v=K1VfdXmqjN8

What Are The Main Processes Of Creating A Basketball?We can divide the processes of creating a basketball in four phases. Each of these phases are here to make sure that the ball has optimal performance. The steps in question are the following:

1. Creating the inner bladder 2.![]() Shaping the interior of the basketball 3. Making the cover of the ball 4. Final testing and analysis

Shaping the interior of the basketball 3. Making the cover of the ball 4. Final testing and analysis Without further ado, let’s dive into each phase of creating a basketball.

Phase 1: Creating The Inner Bladder

The inner bladder is the core of the basketball. It is made from black butyl rubber, a type of rubber which retains air and gives the bounce characteristic to the basketball.

To create the inner bladder of the basketball, this rubber is melted into flat panels. Then, the panels are attached to form the shape of a basketball. Afterwards, one inch-sized hole is pierced in the bladder so that the air filler tube can be installed.

The inner bladder is inflated and left in that state for 24 hours. This is done for clarifying the correctness of the inner bladder.

The inner bladder doesn’t have a perfect shape when it is first inflated. With the help of a machine, the polyester or nylon threads are wrapped around the inner bladder, to create a spherical shape of the ball. Also, the threads will prevent the ball from being deformed.

With the help of a machine, the polyester or nylon threads are wrapped around the inner bladder, to create a spherical shape of the ball. Also, the threads will prevent the ball from being deformed.

Different basketballs use different threads. For example, street basketballs utilize polyester threads, while professional basketballs feature nylon threads.

The cover of the basketball is usually made from diverse materials. High-quality basketballs feature quality leather cover, while other balls feature synthetic rubber or regular rubber.

First, the material of choice is unfolded and cut in six isolated panels that will eventually be wrapped around the basketball. If leather is used, it is stitched together around the ball. Otherwise, if any type of rubber is used, it is held onto the ball with glue.

Then, if the manufacturer wants to customize the basketball with decals or any other graphical information, the marking should be applied by hand at this point. The designs are usually applied via stickers that glue to the ball itself.

The designs are usually applied via stickers that glue to the ball itself.

After injecting the leather patterns on the ball, the graphics will stick to the ball, so all that is left is to remove the sticker, leaving the graphic alone.

The basketball is practically finished its development process. Now, the testing phase remains.

At the end of the basketball development process, a standardized inspection process commences.

First, the bounce aspect is tested. The basketball is dropped from 72 inches, and it must return up to 52 to 56 inches to be fit for commercial use.

After that, some small details like decals and other graphics are checked. Also, any glue leftovers are removed.

After the testing phase, the balls are usually packaged in plastic bags or cardboard boxes and sent out to distributors.

____________________

Now that you know how are basketballs made, you will be delighted to see that we can design your custom basketball free of charge.

Any questions or concerns about basketballs? Feel free to contact us via email or live chat.

How Wilson Makes NBA Basketballs

- Wilson partnered with Horween Leather Co. to create the official all-leather NBA basketball.

- Four key components make up the NBA ball, including an internal bladder, a winding layer, a rubber carcass, and the leather topcoat.

- While mostly science, there’s still a touch of art involved in the ball-making process.

Getting the all-leather NBA basketball into the hoop is the entire point of the game, so coming up with exacting standards for the ball itself is nothing short of a science for Chicago-based Wilson Sporting Goods.

Crafting the NBA ball requires four layers of materials, each with its own defined processes that result in a final uniform product for distribution across the 30 teams in the NBA. Wilson, which served as the ball maker for the first 37 years of the NBA, has regained its status as the official provider of the NBA ball for the 2021–2022 season. Now in its second year of the contract, Popular Mechanics went behind the scenes of the NBA ball-making process.

Now in its second year of the contract, Popular Mechanics went behind the scenes of the NBA ball-making process.

Before production of the ball could start, Wilson met with NBA players and equipment managers to learn the nuances of their performance needs. “They want that consistent feel, whether in Miami or the middle of February in Minnesota,” Kevin Krysiak, senior director of research and development at Wilson, tells Popular Mechanics. “They want the ball to feel the same.”

Every team receives an allotment of new balls each year, though most purchase more for practice facilities. Krysiak and Skip Horween, president of Horween Leather, both say that the NBA being the only league to use a genuine leather ball makes the production process more noteworthy.

The BladderComposed of a rubber mix balanced with a high percentage of butyl rubber and a low percentage of “lively” natural rubber, the bladder controls the ball’s air, which impacts rebound and shape. The butyl is known for quality air retention, allowing the ball to maintain its 8-psi standard while inflating it.

The butyl is known for quality air retention, allowing the ball to maintain its 8-psi standard while inflating it.

According to NBA specifications, when dropped from a height of 72 inches, the ball must rebound 52 to 56 inches. Players don’t want a ball to be too lively; They want to control the force. They also want consistency throughout the game.

To create the bladder, the rubber is placed in a vulcanization mold, which it sits inside for about eight minutes at temperatures between 150 to 160 degrees Celsius. Once molded, there’s nothing to stop the bladder from growing like a balloon when inflated, so Wilson puts between 3 and 4 psi of air in it for handling.

While air certainly accounts for the bulk of the space inside a ball, material from the bladder out is about 5 millimeters thick. The bladder accounts for about 0.8 to 1 millimeter of that.

The Winding LayerImagine thread continuously wrapping the bladder. That’s the winding layer. A mix of both nylon and polyester—a bit heavier on the nylon side to get the right amount of tensile strength for shape retention and rebound—the winding layer “is all about controlling the shape of the ball,” Krysiak says.

That’s the winding layer. A mix of both nylon and polyester—a bit heavier on the nylon side to get the right amount of tensile strength for shape retention and rebound—the winding layer “is all about controlling the shape of the ball,” Krysiak says.

The machine Wilson uses rotates the bladder as the winding is applied, self-balancing to ensure the thread goes on evenly. A small adhesive bath gives it additional structure to keep things from falling apart.

More Behind-the-Scenes Sports Stories ⬇️

- The Engineering Behind U.S. Open Retractable Roofs

- Next-Gen NFL Stats, Delivered Right to Your Couch

- How Millions of Soccer Balls Are Made

Because the bladder starts perfectly spherical, it would quickly turn into an egg without the winding layer. “If you do the winding layer right,” Krysiak says, “it will keep the ball perfectly spherical.”

The Carcass LayerAnother layer of rubber—this a completely different mix than the internal bladder—helps with rebound and structure, and also serves as a canvas for the ball’s cover. Wilson dubs this the “carcass.”

Wilson dubs this the “carcass.”

The mix of styrene-butadiene rubber with natural rubber, which is quite lively, offers the rebound Wilson is looking for. The exact grades of rubber and mix is a ratio the team has massaged over time.

Krysiak says that while 80 percent of the rebound is determined by the internal ball pressure, 20 percent comes from the materials. “You are very much depending on the internal pressure, but there are little nuances we have learned over time that can get us an extra half inch, inch, or inch-and-a-half that we have optimized to meet the performance needs of the players,” he says.

The two-part carcass mold covers the winding layer and goes through its own vulcanization run of 150 to 160 degrees Celsius for about eight minutes. During that time, the hot rubber flows into the winding, giving additional structure to the ball, like rebar in concrete. “How much does it flow into the winding layer and how much does it sit on top of the windings is something we have learned and picked up over time,” Krysiak explains.

When removed from the mold, clean-up and buffing is required to get the carcass ready for the cover layer. The carcass layer also comes with raised channels, allowing the eight distinct cover panels to go on between the raised areas that form the black channels seen on the finished product.

The Leather NBA players are touching 100 percent genuine leather.

The cover material can have a slight impact on the bounce, but the main functionality is feel. “The biggest thing players are looking for is how does it feel when dry or when sweaty and wet,” Krysiak says. “In game performance, it is the one thing we tend to focus the most on.”

Chicago-based Horween, founded in 1905, is responsible for the leather. Using the meat industry’s byproduct steer hides, Horween does an initial chrome-tanned step, preserving the hide enough to be graded based on grain clarity. Once Horween gets the leather to the size and thickness needed for a basketball—about 2 millimeters in the Horween factory, although the finished product goes on a ball at about 1.4 millimeters—the hide is retanned with a blend of tree bark extracts and emulsified oils designed specifically for an NBA ball.

Once Horween gets the leather to the size and thickness needed for a basketball—about 2 millimeters in the Horween factory, although the finished product goes on a ball at about 1.4 millimeters—the hide is retanned with a blend of tree bark extracts and emulsified oils designed specifically for an NBA ball.

Then, the leather is dried in a pasting unit, with starch paste sticking to glass frames that allow the leather to run through a hot-air drier. After that comes the embossing process to create the pebbled texture.

Overall, there is about an eight-step process involved in treating the leather that also includes surface-dyeing the finish for a stain and pigment (heavy on stain) meeting Wilson’s specs.

“This ultimately is a performance product and the better someone is at something, the more they can tell and distinguish the subtleties,” Skip Horween tells Popular Mechanics. He notes that the high amount of tanning solution used as part of the Horween tannage allows the leather to take on the pebbling that gives the ball its texture. It is a finish system they developed with Wilson “to make the ball look and feel the way they want it to look and feel.”

It is a finish system they developed with Wilson “to make the ball look and feel the way they want it to look and feel.”

Related Story

- This Guy Built a Never-Miss Basketball Backboard

“Our ultimate boss is the player,” Horween says. “The combination of the efforts of both companies and these recipes we have developed and evolved are customized.”

New Wilson balls come in a brand-chosen shade of orange, which is baked into the Horween process. Leather, with pores like a human skin, will absorb sweat, oils, and dirt from players’ hands, allowing the color of the ball to darken over time. The raised pebbles on the ball also tend to flatten with use.

Adding the pebbling at the Horween factory involves using an embossing press with a specific plate. “It is a close cousin of the football leather,” Horween says, “but it is definitely not the same. You would probably not play this leather on a football and not play football leather on a basketball. ”

”

Once the finished product leaves Wilson, NBA teams have their own processes for breaking in the ball. Getting the right feel is a subjective process. Games aren’t played with new balls, but ones broken in over time. “Once it is broken in, it is good for a good, long while,” Horween says.

Krysiak says that when a team gets a ball to what they deem the perfect feel, Wilson asks for them to ship it back so they can do testing on it to define the specifications and create new data points.

“It is a very unique feel,” Krysiak says about the genuine-leather ball. “The NBA players tend to equate that completely different feel to the idea that they’ve made it.”

For both Krysiak and Horween, there’s a personal level of having made it, too. “For us, it is always a great privilege when a customer gives us the opportunity to do something like this that when we put our heads together, we get something special,” Horween says. “It is totally amazing to turn the TV on and see a ball and think we played our small part in making it happen.”

“It is totally amazing to turn the TV on and see a ball and think we played our small part in making it happen.”

Basketball - Gosstandart

Basketball - an inflated ball for playing basketball. The ball must be spherical and of the specified shade of orange with the traditional pattern of eight inlays and black stitching. The mass of the ball (officially accepted size 7) is 567-650 g, the circumference is 750-780 mm. Smaller balls are also used: in men's team games, "size 7" balls are used, in women's team games - "size 6", in mini-basketball matches - "size 5".

History

The history of basketball began in 1891, when one of the college leaders of the Youth Christian Association from Springfield (USA, Massachusetts) instructed physical education teacher James Naismith to come up with a new game to entertain high school athletes in the winter. Naismith divided his class into two teams of 9 and hosted the first ever basketball game, which involved throwing a soccer ball into a basket from each side of the hall.

The first basketballs were made from stitched leather petals with a rubber bladder inside. A special fabric lining was used to level the surface of the ball. Molded basketballs appeared in 1942, the color was not yet rigidly standardized, so they played with red, white, and blue balls. For a long time, leather was the main material for the manufacture of basketballs, but the advent of composite materials in the late 1990s revolutionized the production of balls that can withstand the most severe conditions of outdoor play.

All modern balls consist of an inflatable rubber bladder and an outer cover made of leather, rubber or synthetic material. The surface of the ball is almost always divided into "ribs", which are slightly recessed from the surface and have a contrasting hue. The traditional color scheme is an orange ball with black ribs, but others are also found. To improve contact with the player's hands, special small "pimples" are used on the surface of the ball.

Basketball is one of the most popular sports in the world today. It is played by people of all ages, starting from school, and this popularity is only growing every year.

It is played by people of all ages, starting from school, and this popularity is only growing every year.

Varieties

Depending on the location of the playground, there are three types of basketballs: Indoor - intended for the hall, Outdoor - used on the street, and Indoor / Outdoor - universal. Marking is mandatory indicated on the surface of any ball.

Indoor indoor balls are made of genuine leather and synthetic materials, they have the best grip, but the least wear-resistant (they quickly become unusable on asphalt). Professional basketballs have a special microfiber composite coating that muffles impacts and improves contact with the hand.

Outdoor balls are made only from rubber or synthetic materials, they are very durable, withstand heavy loads on asphalt, and also have good grip on the surface.

Indoor/Outdoor all purpose balls are made from rubber or composite materials and can be used successfully on all surfaces. However, it is more correct to still have separate balls for the hall and the street.

Sizes

Basketballs are classified by size. The largest size (size 7) is officially accepted for men's team competition.

| Size | Circumference, mm | Weight, g |

| Size 7 | 750-780 | 567-650 |

| Size 6 | 720-740 | 500-540 |

| Size 5 | 690-710 | 470-500 |

| Size 3 | 560-580 | 300-330 |

According to various estimates, there are from 10 to 35 thousand dots (“pimples”) on a basketball.

Material

The material of the outer cover of a basketball directly affects its playing characteristics. The most common modern materials are rubber, natural leather, artificial leather and composite material.

Rubber balls are the cheapest. They wear out quickly, become slippery, after which they do not hold well in the hand. Their main purpose is to play on paved street playgrounds.

Their main purpose is to play on paved street playgrounds.

Genuine leather balls - a classic, but the most expensive option. They are used in professional tournaments. They can only be played in the hall on a special surface, otherwise they quickly deteriorate.

Artificial leather balls are considered all-rounders and can be played both indoors and outdoors. They last quite a long time, while being relatively inexpensive compared to other balls.

Balls made of composite materials are close in quality to products made of genuine leather, but at the same time they are noticeably stronger and withstand much greater loads.

Selection

When buying a ball in a store, please note that:

- must be inflated to the norm. The norm is when the ball can be pushed a little with your thumb - by 3-5 millimeters, no more. If the ball is under-inflated, then there is a risk that it goes down. If, on the contrary, it is pumped over, then the cord can be deformed from excessive pressure and then the ball will go bumps, the geometry of the ball will be disturbed.

The exception is online stores. In them, balls are usually deflated before shipment, and this is normal practice.

The exception is online stores. In them, balls are usually deflated before shipment, and this is normal practice. - Rebound. A ball thrown from shoulder level (just from outstretched arm) must bounce to the waist. A smaller and larger rebound indicates that it is better not to take such a ball. The rebound must be strictly vertical, the ball moving to the side indicates a curvature of the shape and the presence of a hernia.

- The basketball must be perfectly round. Oval balls, balls with bumps on the surface are not a purchase item.

- The ball must not have any breaks in the covering and no exposed cord.

- The ball must come with a special nozzle for the inflation nipple.

Commenting system SigComments

Didn't find what you were looking for? You can leave a request in the feedback form.

Portal Gosstanart.info does not carry out commercial activities, does not cooperate with advertisers, manufacturers of goods and companies providing services. Please do not make commercial offers! All information presented on the portal is the result of independent research and is freely distributed information.

Please do not make commercial offers! All information presented on the portal is the result of independent research and is freely distributed information.

Home Portal news Blacklist Archive Feedback

History of basketballs

What balls are played now and how did it happen?

What balls are played now and how did it happen?

YOU THINK WHY WE DO NOT PLAY A FOOTBALL OR A VOLLEYBALL? WHICH BALL DID IT ALL START WITH?

In 1891, James Naismith invented basketball. Then the game was very different from ours. For example, there was a bottom in the baskets and every time after a hit, the ball had to be taken out. Then they also played football ...

In 1891 James Naismith invented basketball. Then the game was very different from ours. For example, there was a bottom in the baskets and every time after a hit, the ball had to be taken out. Then they also played football…

Anyone who has ever tried to play basketball with a football knows that this is not the best thing to do. It is inconvenient to handle it in gears and lead. Therefore, 3 years after the first game, the first basketball was invented.

It is inconvenient to handle it in gears and lead. Therefore, 3 years after the first game, the first basketball was invented.

This ball was made of leather strips with a rubber bladder inside and was sewn up with threads on the outside.

By 1929, it was improved: the laces were hidden, and the shape itself was changed for a better and more predictable rebound.

In 1937 the lacing disappeared from basketballs, and in 1942 the balls were already similar to ours, they were no longer sewn and they kept their shape better.

Perhaps this had a strong influence on the development of the game, because even in the 50s dribbling was very far from ours. Most of the players then skillfully dribbled with only one hand and very rarely used transfers.

Until the late 1990s, leather was the main material used in professional league balls, but since then it has been increasingly replaced by synthetic materials.

In 2020 there are already balls for every taste and color: plain, multi-colored, small, large, rubber, leather, weighted, recycled plastic and other modern materials.

What balls are currently played:

Mini basketball (under 13) uses a size 5 ball with a diameter of approximately 70 centimeters and a weight of around 0.48 kg.

Women's basketball uses size 6, diameter 73 cm, weight 0.55 kg.

In men's basketball - size 7, with a diameter of 77 cm and a weight of 0.61 kg.

There is also an exception - 3x3 basketball, where they play with a special ball, which is like a size 6 in diameter, but weighs like a size 7. This was done on purpose so that it would be less affected by the wind outside.

Interesting fact

Since 1970, the NBA has only played Spalding balls, but from the 2020-21 season they will start playing with new Wilson balls.

Playground collaborated with Wilson to make their own ball based on the Wilson Evolution. This ball uses an advanced microfiber coating to help give the ball the best touch feel for all dribbling enthusiasts.