Home »

Misc »

How to put a basketball pole in the ground

How to put a basketball pole in the ground

How To Install an In-Ground Basketball Hoop

How To Install an In-Ground Basketball Hoop

- Factors to Consider When Buying a Basketball Hoop

- How to Install a Basketball Hoop In-Ground

- Why Should You Have a Professional Install Your Basketball Hoop?

- Choose Superior Play Systems® for Your Basketball Hoop Installation

If you and your family love basketball, you may be dreaming of having your own hoop right in your yard. There are several different types of basketball hoops available, but an in-ground system offers the most stability and professional-level play. Here’s everything you need to know when shopping around for a basketball hoop, how to install a basketball hoop, and why you should consider professional installation.

Factors to Consider When Buying a Basketball Hoop

When you’re looking to buy a basketball hoop for your home, there are many things to consider, including where you’ll install your basketball hoop and what type you’ll need.![]() A basketball hoop can be a big purchase and a big decision for your property, so you’ll want to make sure you get the best kind for your family and install it in the best location. Here are some of the most important things to think about before you buy your basketball hoop:

A basketball hoop can be a big purchase and a big decision for your property, so you’ll want to make sure you get the best kind for your family and install it in the best location. Here are some of the most important things to think about before you buy your basketball hoop:

1. Choosing a Seller

An in-ground basketball hoop is a large purchase, so you’ll want to make sure you choose the right seller. The best sellers are those that offer post-purchase support such as installation and customer care. Superior Play Systems® is the safest and most trusted name in play and offers high-quality in-ground systems from PROformance Hoops®. When you purchase your basketball hoop from us, we’ll work with you to provide a seamless installation process that gets your family on the court in no time.

2. Location

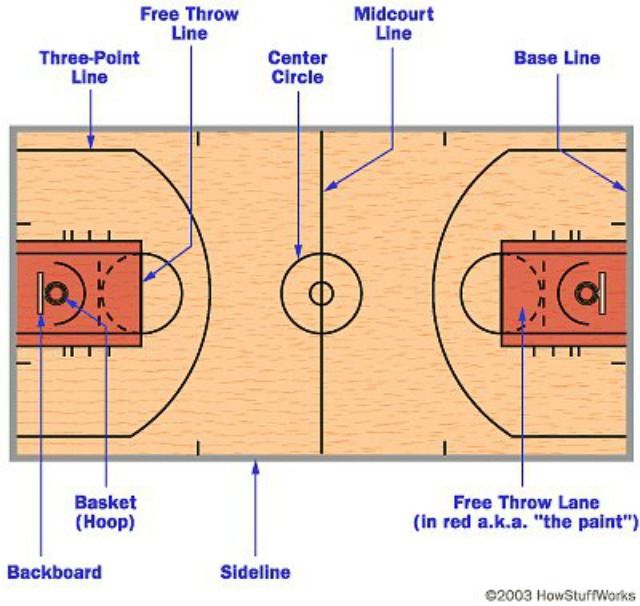

One of the most important factors to consider is selecting the location for your new basketball hoop. The most popular choice for a basketball hoop placement is in a driveway, but you should make sure that you have a level driveway, as it’s much harder to play when the driveway is on an incline. If you have a larger backyard and enough room in the budget, you may want to consider a dedicated area or even a full-size basketball court. Just be sure that you have a patio or paved area — a basketball just doesn’t bounce in the grass. The hoop should not be hanging over the street to keep players safe. It’s also a good idea to check for any local and neighborhood ordinances or homeowner’s association rules for any restrictions on basketball hoop installation or placement.

If you have a larger backyard and enough room in the budget, you may want to consider a dedicated area or even a full-size basketball court. Just be sure that you have a patio or paved area — a basketball just doesn’t bounce in the grass. The hoop should not be hanging over the street to keep players safe. It’s also a good idea to check for any local and neighborhood ordinances or homeowner’s association rules for any restrictions on basketball hoop installation or placement.

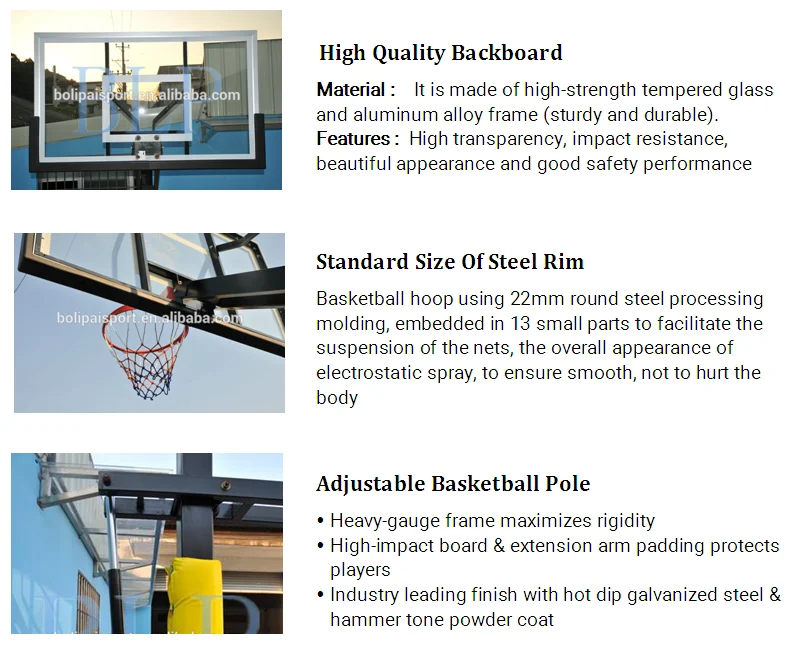

3. Backboard Size

The size of the backboard on a basketball hoop can affect the shot opportunities into the hoop, and generally bigger is better here. However, you’ll want to think about the size of your driveway or the place where you are installing the hoop. In a small driveway, a too-large backboard can overwhelm the space, or look out of place. Consider also the level of professionalism you want — if you have a child with aspirations for professional basketball, a 72-inch backboard is regulation size, and would give the best practice for real basketball courts. However, a larger backboard is more expensive and may not be necessary if the hoop’s main purpose is for family recreation.

However, a larger backboard is more expensive and may not be necessary if the hoop’s main purpose is for family recreation.

4. Height

You’ll want to think about the height of the basketball hoop before you install, making sure that it fits in with your location of choice. Professional regulation height is 10 feet for a basketball hoop, but just as with backboard size, you may want to go with an adjustable hoop or a shorter hoop if its just for fun. You can also check out hoops with adjustable height so it can grow along with your kids. Also consider the size of the overhang — the distance between the pole and the backboard, making sure to have about 2.5 to 4 feet of overhang available.

5. Type of Pole

Selecting a pole for your basketball hoop may seem simple, but there are actually many choices available. Poles come in both round and square shapes, in sizes between 4 and 6 inches, and either as a single piece or a multi-piece system. Poles are generally made of metal and are either painted or have a powder coating.

6. Net and Rim

Standard basketball setups have an 18-inch diameter rim, with hooks to attach the net. There are two main types of rims available for home basketball hoops — static and breakaway. A static rim stays in place without moving, and is a great option for beginners or as a more economical choice, but should not be used for dunking. If you anticipate some slam dunks on your home setup, a breakaway rim is the best choice. These rims include special springs that flex and absorb the force of the dunk. This protects the safety of the player, as well as the longevity of your basketball setup.

Once you’ve considered all of the options available for your basketball hoop, you can decide what is best for your family and your location. Next, it’s time to purchase the basketball hoop setup and install it in your yard.

View PROformance Hoops® Installation Guides & Owner’s Manuals Here

How to Install a Basketball Hoop In-Ground

You’ve done your research and found the right basketball hoop for your family — now it’s time for the exciting part! Installing your basketball hoop can be a lot of work, but here, we will lay out all of the steps involved. You’ll have your own basketball hoop up in no time and ready for the whole family to shoot some hoops! Consider this your step-by-step basketball hoop installation guide:

You’ll have your own basketball hoop up in no time and ready for the whole family to shoot some hoops! Consider this your step-by-step basketball hoop installation guide:

Step 1: Choose Your Location and Call Before You Dig

As mentioned in the section on things to consider, one of the most important steps in the basketball hoop installation process is choosing the right location. You may have already picked the location where you want your basketball hoop, but since you’ll need to dig a hole, it is a must that you Call Before You Dig (dial 811) to check for any utility lines. Ask your Superior Play System for more info.

Be sure that you’ve checked with any neighborhood ordinances or homeowner’s association rules on the placement of your in-ground basketball hoop on your property. You should also read all the instructions and check for any manufacturer recommendations for your particular model before you start digging.

Step 2: Dig a Hole

You’ll need to dig a hole where the pole for the basketball hoop will be located. Check with your manufacturer and your specific model for recommendations on how to dig the hole, and how big it should be. You can dig by hand with a shovel, or use an auger or other digging equipment. See owners manual for specific instructions.

Check with your manufacturer and your specific model for recommendations on how to dig the hole, and how big it should be. You can dig by hand with a shovel, or use an auger or other digging equipment. See owners manual for specific instructions.

Step 3: Pour the Concrete

Once you’ve dug the hole, you’ll secure the basketball hoop pole in the ground with poured concrete. Some models simply have a single pole that you pour the concrete around. If this is the case, have someone — or two people — hold the pole level while another pours the concrete around it. More commonly, there is a rebar-mounted anchor that you’ll set into the concrete after it’s been poured. Either way, as you’re pouring the concrete, make sure to regularly agitate it with a shovel to remove any pockets of air.

To finish off, smooth out the top of the concrete with a trowel, and make sure everything is level. Clean off any excess with a damp towel or sponge. Now, you’ll have to leave the cement to dry for at least 24 to 48 hours. For the first few hours, keep checking the cement to make sure that the pole hasn’t shifted and isn’t leaning. Correct the pole if necessary and keep re-checking until the cement has hardened. Wait on the rest of the assembly until the cement has dried and hardened completely.

For the first few hours, keep checking the cement to make sure that the pole hasn’t shifted and isn’t leaning. Correct the pole if necessary and keep re-checking until the cement has hardened. Wait on the rest of the assembly until the cement has dried and hardened completely.

Step 4: Raise the Pole

If your basketball hoop setup is simply a pole in the cement, you can skip ahead to the backboard. But if your setup includes a mounting anchor, it’s time to assemble and raise the pole. Each model is a little different, so be sure to follow the directions for your specific unit. If you have an adjustable-height type of basketball hoop, you’ll assemble the lift mechanism and support arms according to the directions.

The post will likely be very heavy and may require a few people to lift it into place. Take any necessary safety precautions, and have your team lift up the pole so that it matches up with the anchor piece in the cement. Make sure that the post is level, and use the bolts to secure it into place. Leveling nuts should also be a part of the setup — adjust these as necessary to make the pole completely level.

Leveling nuts should also be a part of the setup — adjust these as necessary to make the pole completely level.

Step 5: Attach the Backboard

In some basketball hoop setups, the backboard is attached before the pole is raised, but with many upscale models, you’ll attach it after the pole is secured. Note that the backboard is also generally very heavy, and it may take several people working together to lift it up and get it installed. Make sure you have a few extra helpers around and take precautions for safe lifting.

Have several of your helpers lift the backboard up in place to the support arms, while another person secures it to the support mount. Each model is different, but there may be other support arms or cross braces to attach at this point. Follow the directions to get all of the right parts securely in place.

Step 6: Install the Rim and Net

When the backboard is fully attached, it’s time to add the basketball rim and net. The rim will simply get bolted to the backboard in place. If you’ve opted for a breakaway rim, there may be some extra assembly required. With the rim attached, you can then loop the net around each of the hooks on the rim to have your net fully installed.

If you’ve opted for a breakaway rim, there may be some extra assembly required. With the rim attached, you can then loop the net around each of the hooks on the rim to have your net fully installed.

Step 7: Finishing Touches

By this point, your basketball hoop is almost ready to play! There are just a few extra steps to fully finish and customize your setup, some of which are optional. Some upscale models have extra padding that you can attach around the corners of the backboard, and around the pole. These are generally optional touches, but can ultimately protect the safety of any players, preventing bumps and bruises, or other injuries when accidentally bumping into the basketball hoop.

If you have an adjustable-height basketball hoop, you can now adjust to the desired height for your family. It may be necessary first to place it at the regulation 10 feet so that you can mark the height on the pole or use provided height stickers. Measure the height of the rim to check for accuracy. Now it’s ready to adjust to whatever height you want to use — with the height stickers, it’s easy to see at a glance where to adjust the mechanism.

Now it’s ready to adjust to whatever height you want to use — with the height stickers, it’s easy to see at a glance where to adjust the mechanism.

If you have any additional accessories, such as court lighting, now is the time to install these. Follow the manufacturer’s instructions for any accessories to get them installed properly. Depending on the size of the area where you install your hoop, you may want to paint court lines on the pavement. This is totally optional, but if you choose to paint lines, pressure wash the area first to ensure you have a clean surface for the paint to adhere to. Measure out where the lines need to be and mark off with painter’s tape. Paint in your lines and remove the tape. Now you’re truly ready with your very own basketball court! Gather up the family and get ready to play!

Why Should You Have a Professional Install Your Basketball Hoop?

If following these basketball hoop installation tips and steps has your head spinning, you’re not alone. Even in today’s DIY culture, installing a basketball hoop yourself can be a bit involved. If you decide that installing the system yourself is just a little too much, why not let the professionals handle it? With professional installation, you’ll save yourself a lot of time and hassle.

Even in today’s DIY culture, installing a basketball hoop yourself can be a bit involved. If you decide that installing the system yourself is just a little too much, why not let the professionals handle it? With professional installation, you’ll save yourself a lot of time and hassle.

Consider the amount of time necessary to complete the installation process yourself. Even if you follow every direction exactly, the process still involves at least two days of work. And any delays in the process or simple mistakes can drag it out even longer. Even the research and preparation work can take more time than expected.

Installing an in-ground basketball hoop can also take a lot of tools and specialized equipment. Digging a hole large enough for the basketball hoop post is not easy to do by hand, and if you don’t have an auger or backhoe, you may need to rent equipment to complete the task. This can add time and expense to the project. Consider also the fact that you will need extra adults around to help. Raising the heavy pole and lifting up the backboard require at least three to five adults, so you’ll need to convince family, friends or neighbors to help out, possibly spending money on food and drinks to feed and thank your crew.

Raising the heavy pole and lifting up the backboard require at least three to five adults, so you’ll need to convince family, friends or neighbors to help out, possibly spending money on food and drinks to feed and thank your crew.

Attempting a project of this scale can lead to a lot of aggravation, especially if you lack the proper tools or underestimate the amount of time and effort necessary to complete the project. Even when everything goes right, the amount of time and effort required for a project of this scale can simply be frustrating.

Having a basketball hoop in your yard should be about fun, not frustration. And having a professional install your hoop means you can get to the fun part much faster. When you buy your basketball hoop from Superior Play Systems®, you get some of the best equipment on the market as well as white-glove installation services. The experience and expertise of the professionals mean they can get the job done faster and easier than you could on your own, and you know it will be done correctly the first time.

Choose Superior Play Systems® for Your Basketball Hoop Installation

If you’re shopping around for a basketball hoop for your family, come to Superior Play Systems® and experience the best in expertise and customer service. Our experts can help you every step of the way, from selecting the right equipment for your needs to scheduling professional white-glove installation services. To get started, contact Superior Play Systems® today — we can answer any of your questions and help you find the right basketball hoop for your family. Shop our equipment online or use our search tool to find the closest showroom where you live. Come experience our top-quality equipment and superior customer service in person!

How To Install Your Own Inground Basketball Hoop

Home > Guide to Hoops / Goals > How To Install Your Own Inground Basketball Hoop

If you love basketball and want to practice your shots any time of the day, purchasing your own basketball hoop is the best option.

There are a number of different basketball hoops available, but in-ground hoops are a better option because they provide you with stability and professional-level experience.

There is a lot to consider when purchasing a basketball hoop e.g. choosing the right seller, the perfect location, the ideal backboard size and the type of pole etc.

If you are having trouble knowing what suits you best, check out our Home Hoops Guide.

Know what you want, but don't know where to find it? Check out some high-quality stuff here.

This article is a step-by-step guide on in-ground basketball hoop installation.

Before You Begin with The First step, Keep A Few Things In Mind

- Find a suitable ground where you can fit your basketball hoop. The area must ideally be flat and paved e.g. driveways. The ideal scenario should be to have enough space to accommodate your hoop and the number of players.

- Overhang is the distance between the pole and the backboard, and affects how much room you have to land after you shoot layups.

For good balance and safety, 2 feet to 4 feet of overhang is ideal. Anything greater than that could cause shaking because the weight of the backboard would

be suspended too far.

For good balance and safety, 2 feet to 4 feet of overhang is ideal. Anything greater than that could cause shaking because the weight of the backboard would

be suspended too far.

- Take into consideration the position of the sun when installing your basketball hoop. Face the hoop towards the north, so the sun does not get in your eyes.

- Make sure the goal is at least 20 ft. (7m) from any overhead power lines, and no overhead power lines are within a 20 ft. (7m) radius of the goal.

- Make sure you have enough room to shoot 3pt shots at tops, wings and corners. If you want to have a regulation three point line as well as some room behind it, 28 - 30 ft from the pole is what you need. For a full three-point arch, you need around 40 ft of width.

- Before you dig a hole, you must contact Call Before You Dig (dial 811) to check for any underground power, gas, telephone, water and other utility lines.

Tools and Materials: Spade, Wheelbarrow, Shovel, Cement Trowel, Tape Measure, Stir Rod, Level, Auger, Hoe, 10-14 60 lb Bags of Dry Concrete Mix, Water, Rubber Mallet, 1/2" Drive Torque Wrench, Steel Punch, Screwdriver, Stepladder.

1. Dig A Hole

Digging the perfect hole for your basketball hoop is vital.

The most important thing to keep in mind is that the hole is deep enough, and of the right size, so the metal bars that form the anchor fit perfectly. This will provide stability to your basketball hoop.

You can dig by hand with a shovel, or use an auger or other digging equipment.

The hole should be 48" to 50" (1.2 m - 1.3 m) deep and 16-18" (0.4 m - 0.5 m). Follow the instructions manual to check the exact measurements required for the hole.

Remember, a strong foundation is your key to success!

2. Pour The Concrete

Now that you have dug the hole, the next step is to pour the concrete.

Installing an in-ground hoop would require 10-14 60lb bags of concrete, but it is recommended that you buy an extra bag or two just in case you need them.

Mixing the concrete can be a tricky procedure. You need to make sure that the right amount of dry concrete and water is used. If the mixture is too thin, it will lack the strength required to hold the pole, and if it is too thick, you will struggle to fill voids.

If the mixture is too thin, it will lack the strength required to hold the pole, and if it is too thick, you will struggle to fill voids.

For a 60lb concrete bag, 1.9 liters of water is PERFECT!

To prepare the concrete mix, pour dry concrete in a container and create a depression at the center of the dry mix. Add water, and mix thoroughly until it's firm enough. Do not allow the mix to sit for a long period of time or it might dry out.

Fill half of the hole with concrete, and insert steel bars inside. Make sure the bars are properly aligned. Once the bars are aligned, fill the hole with concrete and level it using a trowel tool. Make sure the surface is smooth and there are no pockets of air.

When the above is done, place the assembled anchor in concrete, and push it down the concrete solution. It must be fixed deep enough so it provides stability to the basketball hoop.

It is important to make sure the assembled anchor is completely level!

Give the concrete at least 72 hours to cure, in case the weather is warm. For cooler surroundings, wait an extra day or two.

For cooler surroundings, wait an extra day or two.

3. Fix The Main Pole

In-ground basketball hoops come with one-piece, two-piece and three-piece poles. A one-piece pole is highly recommended because it minimizes vibration and shake. It is also rust and corrosion resistant.

A 4"-6" diameter pole provides excellent performance and stability. Shape-wise, square poles are preferred over round ones because they are more rigid.

A 7-gauge thickness on the pole is preferred over 11-gauge because the former is the STRONGER choice. A thicker pole provides you with a better playing experience. It is stronger, causes less shake, and provides greater durability and professional experience.

Fixing a pole depends on the type of anchor being used.

There are two types of anchors used in in-ground basketball hoops: the threaded j-bolt and the hinge anchor system.

The latter is easier to install.

With a j-bolt anchor system, you will have to lift the pole above the anchor, position it rightly, and then bolt it down to the j-bolt anchor. This process will require greater physical effort as you will have to go up and down a ladder to attach the backboard,

extension arms and the hoop.

This process will require greater physical effort as you will have to go up and down a ladder to attach the backboard,

extension arms and the hoop.

The hinge ground anchor system, on the other hand, is simpler to install, and does not require much physical effort. You can assemble the pole, extension arms and the backboard on ground, and then align the pole using the hinge mechanism. The pole is then placed

in an upright position, and secured with a bolt.

A huge advantage of the hinge ground anchor system is that it can be easily moved from one place to another. When you move, you can take the fully-assembled pole with you and relocate it without much hassle.

Do not forget to follow the instructions manual.

4. Install The Backboard

There are three main types of backboards: acrylic, tempered glass, and polycarbonate. For a professional experience, tempered glass is the BEST CHOICE!

Out of the three, the tempered glass provides the best bounce and spin. It is also shatter proof, and therefore safe.

It is also shatter proof, and therefore safe.

Acrylic backboard is suitable to use in public places. However, it does not provide the same bounce and spin as the tempered glass backboard.

In some basketball hoop setups, the backboard is already attached to the pole, but for hoops with a separate backboard, there are a few things that one must keep in mind before installation.

Since the backboards are heavy, it is advised to use additional manpower to lift and install the backboards, while taking safety precautions. Lift the backboard up in place to the support arms, and secure it to the top mount.

5. Install The Rim And Net

Choosing the best rim for your hoop is another important step. This piece of the system absorbs the greatest physical impact, and therefore, must be durable.

A breakaway rim is recommended. It consists of a hinge and spring at the point where it attaches to the backboard, and can bend downward when a player dunks. It is DURABLE.

Once you have chosen the perfect rim, installing it would not be much of a problem.

All you have to do is fix it with screws to the backboard. Then loop the net around each of the hooks on the rim to have your net fully installed, and you are all ready to SHOOT!

Hire A Professional To Do The Job

If you have prior experience in installing a basketball hoop, or doing similar work, you might consider installing the hoop yourself.

However, hiring a professional to do the job can save you from damages, injuries and unpleasant situations since installing a basketball hoop requires a number of tools, and expertise.

Consider this: if you are going to install it yourself, you will have to buy or rent the tools, request for additional manpower, and the overall process will likely be slower than when done by a professional.

Knowing that you have spent quite a lot of money on purchasing the setup, you would not want to risk damages to save a few dollars.

Need Help?

Contact us if you have any questions, need help with installation or need any help choosing a basketball hoop. Our experts are here to help.

What do you think? Let us know by leaving your comments, suggestions, and questions... To what depth and in what way should the posts be buried when building a fence

Depth of fence posts

Depth of fence posts is an important point. Factors influencing the installation depth of the posts: the underground part of the fence posts experiences 2 types of loads:

Static vertical load acting from top to bottom. Its value depends on how much the structure weighs. Each stanchion bears half the weight of the two adjacent sections, plus its own weight.

Dynamic. It exerts lateral pressure on the fence at different angles and with different force from gusts of wind, which causes a bending moment at the border of the underground and aboveground parts of the supports.

These 2 types of loads are taken into account depending on the design of the fence. If it is planned to build pillars of brick and make spans of stone or forged elements, then in this case it is necessary to calculate the static load, since it prevails over the wind load. Then the installation depth is more dependent on the subsidence characteristics of the soil and the area of \u200b\u200bthe sole of the foundation.

In the construction of light continuous fences (for example, from corrugated boards), a significant role is played by the lateral wind load acting on the bending of the post. For a fence from an unedged board with an average mass, both types of loads must be taken into account.

To find out how deep to dig the fence posts, many factors must be taken into account:

the weight of the structure;

her windage;

soil properties on the site;

distance between adjacent supports.

It is rather difficult for an ordinary developer to calculate how much dynamic and static load a particular type of fence will have. There are ready-made solutions that have been proven by many years of practice on various types of soil.

There are ready-made solutions that have been proven by many years of practice on various types of soil.

Installation in dense soil

Dense sandy or clay soil is most convenient for installation of a fence of any design. When building light fences, the following methods of installing supports are used:

simple driving into the ground;

backfill;

driving with concreting of the upper part.

Whichever method you choose, it is pointless to immerse the posts deeper than 1 m, and the optimal depth, tested in practice, is 80 cm. Speaking of how many centimeters of the length of the posts should go into the ground, it is understood that the hedge section has standard dimensions: width span - 2.5 m, height - 2 m. They are lightweight and windage, so you can do without digging a hole and concreting. Just do not immediately hammer a steel pipe into the ground with a sledgehammer, as a result, it will still stagger. It is necessary to drill thin wells (less than the section of the rack) 80 cm deep and carefully drive the posts into them.

The backfilling option is suitable for installing a solid fence made of wood or profiled sheet. The work is carried out as follows:

Dig holes to a depth of 0.9—1 m, pour sand (cushion) on the bottom and tamp.

Position the support, align it vertically and secure.

Pour crushed stone and stones into the cavity, performing a layer-by-layer compaction. For fidelity, you can fill the backfill with a liquid solution of clay, in this case add a layer of crushed stone to the pillow.

When the topsoil is loose, partial concreting of the posts is used. It is necessary to dig holes of only 40 cm, and then drive racks into them to a depth of 40-50 cm. Then pour the bottom with crushed stone and pour concrete to the ground level.

During the construction of a heavy stone fence, the depth of the columnar foundation is determined by the location of dense soil horizons. It is impossible to support a heavy structure on black soil or other loose soil, so you will have to go deep to compacted dry clay.

Installation on subsiding soils

These include clay and other soils with low density (loess). With the appearance of a load and moisture, such a soil gives an additional drawdown, whose value depends on the strength of the impact. Therefore, to install a light fence from a mesh or profiled sheet, you can use the same methods - driving and backfilling. The immersion depth is calculated according to the following rule: the underground part of the support should be 1/3 of the entire length.

To prevent heavier hedges from sinking, the weight must be distributed over a larger area. To do this, the pits are made wider, and steel sheets are welded to the bottom of the racks before installation. Then the method of full concreting of the pillars is applied, which prevents lateral swinging by the wind.

When installing a stone fence with heavy wrought iron gates, you need to rely on horizons that are not subject to subsidence. The depth to which the reinforced concrete foundation will have to be buried depends on the region of residence, it can be from 1 to 2 m. There are 2 ways to reduce the cost of building such a foundation:

There are 2 ways to reduce the cost of building such a foundation:

arrange a shallow foundation of a strip type together with columnar foundations;

use screw piles that go into stable soil layers.

Piles having a fulcrum are not afraid of either vertical or lateral influences. To distribute the weight of the fence, their heads are combined with one concrete slab - a grillage, from which the brickwork begins.

Supports in heaving soil

When it is necessary to place posts in the construction of any fence on waterlogged heaving soils, it is important to know the depth of freezing. It depends on how many meters of the rack will go underground. The fact is that in winter, ground moisture turns into ice, which causes the soil to swell and push out all foreign bodies.

There are only two ways to solve the problem:

Drill wells 50-60 cm below the freezing line, install metal poles and concrete. Moreover, the concrete layer should not rise above this boundary, and the rest of the cavity should be covered with crushed stone and sand with a rammer.

Use screw piles going into non-freezing ground levels.

It is inappropriate to consider other options due to the too high cost of building such a fence, because in some regions the soil freezes to a depth of more than 2 m. Therefore, heavy fences have to be installed only on piles, and light fences - on pillars with a concrete sole located in non-freezing soil.

Concrete poles in the fences from the "Eurofence" in the recesses will be concreted correctly. At the same time, the recesses make the cone-shaped base of the cone down - this shape will compensate for the buoyant effect of frost heaving. Having inserted a post into such a hole, it is poured with a concrete solution with fine-grained gravel. For concrete grade 150 kg / cm2, take 200 kg of cement, 920 kg (0.54 m3) of quartz sand, 980 kg (0.65 m3) of dolomite or limestone crushed stone and from 90 l to 130 l of water. We get concrete with a density of 2100 kg / m3. Between the supports in their side grooves, you need to put wooden spacers, the length of which is equal to the length of the fence sections.

Supports for gates and gates:

Additional supports must be dug in at the places where gates and gates are located and it is possible to install hanging curtains on them.

*****

Certificate SK

In the Crimea, when installing supports, it is recommended to use full concreting of the underground part of the pillars with the manufacture of a cushion of crushed stone due to the fact that the depth of soil freezing in Crimea is not more than 30 cm, the amount of precipitation is minimal, groundwater is practically absent, the average daily temperature is above zero (frequent thaws are typical for the winter period, the absence of a stable snow cover) - that is, swelling of the soil does not threaten the fence.

Reliable support for a strong fence - Realnoe Vremya

Real estate

00:00, 06/29/2022 Plot: House in focus

5 questions about how to choose and install the correct support posts for a quality fence

If the fence falls, sticks out of the ground, or shows other signs of "unstable nature" - as a rule, the pillars are to blame. Or rather, not they themselves, but those who chose and installed them incorrectly. We understand what pillars are, what they can be made of and what to provide for when installing them.

Or rather, not they themselves, but those who chose and installed them incorrectly. We understand what pillars are, what they can be made of and what to provide for when installing them.

What materials are used for support posts? Guardrail posts can be divided into three main groups according to the material from which they are made.

Wooden poles are made from solid logs or sanded logs. This is a rather capricious material, because the tree will have to be reliably protected from rot and moisture - after all, such a pillar is dug directly into the ground. This is done either by means of special impregnations, or by simple wrapping with roofing material. Therefore, as a rule, such supports are installed by those who have unlimited access to cheap wood - after a while, wooden supports will need to be changed. The cross section of the beam should be at least 10x10 cm if the fence is low (up to one and a half meters), and 15x15 cm if the height is 2 m or more.

Metal supports are the most popular option. As a rule, pipes of the most diverse profile are used (both round, and rectangular, and square). Most often, in areas, metal poles stand straight as they are, in their original form. But if the highest decorative effect is important, then they are covered with stone or brick - a stone pillar reinforced with a metal core is obtained.

Stone pillars - not the cheapest option and not the easiest to arrange. If it is not reinforced with a metal core, then this option is possible if the entire fence is assembled from stone (laid into a metal mesh mold).

Photo: doka-metal.ru

What is a fence shoe and why is it needed? This is an intermediate option between a wooden post and a metal one. If you really want a beautiful wooden beam, but you don’t want to process it and change it every five years, then shoes come to the rescue. These are short metal poles, the upper part of which is hollow and is a kind of "shaft" - a wooden bar is inserted into it. Thus, all the moisture from the ground does not get on the tree - the pole is reliably protected by a metal shoe. In this case, waterproofing is performed between metal and wood. Such wooden poles can last quite a long time - up to 15 years.

Thus, all the moisture from the ground does not get on the tree - the pole is reliably protected by a metal shoe. In this case, waterproofing is performed between metal and wood. Such wooden poles can last quite a long time - up to 15 years.

Can any thickness be chosen for the metal pole? The wall thickness of the metal pole is important. It should be at least 2 mm, and even better 3. But the thickness of the profile section can be arbitrary. True, it determines the maximum width of the span between the pillars. For example, you can buy a pipe with a section of 60x60 mm and a wall thickness of 2 mm - and then the spans will be two or three meters long. If the parameters of the metal pole are smaller, you will have to put them every one and a half meters, and this will cost both more and more labor-intensive.

At the same time, it must be remembered that the entrance group must be reinforced, because the operational load on the gate and gate is higher than on the rest of the fence. So the pillars for these zones should be more massive. For example, it is desirable to make gate posts with a rectangular profile, with a section of at least 100x120 mm.

So the pillars for these zones should be more massive. For example, it is desirable to make gate posts with a rectangular profile, with a section of at least 100x120 mm.

Photo: ideal43.rf

How deep should the posts be buried? The installation depth of the poles depends on how deep the soil in our area freezes. Another important parameter is how much windage the main material of the fence will have. For example, a profiled sheet is a material of amazing windage, so the supports need to be dug in deeper than if you have a picket fence between the posts, which quietly passes the wind.

The depth of soil freezing is a standard value, it is in the tables for each region. For example, in Kazan it is determined on average as 170 cm. But it also depends on the type of soil - for example, sandy loam freezes deeper than loam.

So, the fence post must be lowered below the freezing depth - if the fence is made of mesh, for example, then 10 cm below the freezing level is enough.