Home »

Misc »

How to build a cheap outdoor basketball court

How to build a cheap outdoor basketball court

How to DIY Build a Basketball Court (8 Step Guide)

Inspired to build your own backyard basketball court?

If you're interested in DIY'ing a basketball court or having a local contractor install a court for you then you've come to the right place.

Last Updated 2nd of April, 2020.

1. Choose the Size and Location of Your Court

Ideally you’ll choose a location that is reasonably flat, to keep excavation needs to a minimum.

Recommended subsurface base: Concrete (100mm thick, 25MPA, Reinforced, Helictoper/smooth finish, Standard slope to allow water to drain off the slab)

We strongly recommend a concrete base for any new base being built for a MSF PRO sports court. Concrete provides by far the best longevity, performance and value over the long run and requires virtually no ongoing maintenance or repairs for many years. Other suitable bases include Pavers, Asphalt or Decking.![]()

- Option 1: Have an elevated concrete slab & then fit your landscaping requirements around it.

- Option 2: Level the slab with the rest of your backyard. This option involves more excavation work/costs.

The size of a full size NBL court is identical to the FIBA regulation sized basketball court of 28m x 15m (420sqm), which is usually too large to fit into the average backyard. We recommend considering a half court, which can be customised to suit your space. Sizing can range from very small approx 4m x 6m (24sqm), 9m x 5m (45sqm), 10m x 7m (70sqm) to a 3X3 regulation half court of 15m x 11m (165sqm).

Precise measurements and planning are crucial in order to end up with the best result.

2. Purchase the Hoop & Sports Court Surface Tiles

The in-ground Hoop anchor kit should be installed during the concrete pour, so ensure you’ve ordered your Hoop in time to arrive before you schedule the concrete. Take note of the hoop's overhang in centimetres so you can plan accurate placement of the hoop anchor, free throw and three point lines.

Surfacing your court with a specially designed synthetic sports surface such as Australia's #1 selling, top rated MSF Pro™ will not only produce an amazing looking result, but will also provide more accurate ball bounce, sound reduction and minimises joints strain/injuries.

3. Level the Ground

Prior to concreting, the space must be dug up and levelled. If you require the concrete to be flush with the surrounding ground then you must excavate 115mm below surface level to allow for the concrete slab (100mm) and sports surface tile (15mm). If you are opting for the elevated slab then you may not need to excavate but you do need to remove any grass and level the ground.

IMPORTANT SAFETY PRECAUTION: Before you dig, call 1100 (Australia) or your local utilities to rule out the presence of buried cables including power, water, gas and phone lines. Failure to do so could result in serious or fatal injury. Dial Before You Dig is a FREE national referral service designed to assist in preventing damage and disruption to Australia’s vast infrastructure networks which provide essential services we use every day.

4. Pour a 100mm Concrete Slab

Prepare and pour a 100mm thick slab of concrete (25MPA, reinforced, standard slope, helicopter/smooth finish) matching your exact MSF PRO™ Court Design measurements. Ensure you have someone experienced with concrete slabs on hand for this step. Plan the concreting for when the weather is dry and allow for 72 hours to let the concrete set.

It's recommended to install the hoop anchor at the same time as pouring the slab to save on expenses. The recommended hole size for a hoop anchor system is approx 500mm x 500 mm and 1.2m deep. Please note: Always remember to closely follow the installation & safety instructions that come with your in-ground hoop.

Always be sure to follow the official basketball hoop installation instructions. Goalrilla in-ground hoops generally require 3-5 strong labourers with multiple ladders and power tools. Hoop installation can take up to a few hours for those inexperienced with installing. The below videos provide an example of the procedure involved for installing a popular Goalrilla in-ground basketball hoop system yourself...

The below videos provide an example of the procedure involved for installing a popular Goalrilla in-ground basketball hoop system yourself...

How to Make a Basketball Court Cheap

Basketball is one of the most approachable sports globally because it does not require a lot of things for you to play it. You can play the sport as long as you have a hoop 12 feet high off the ground. But it still is better to have a court if you want to play the sport because of how it will allow you to play a full game with other people. And the good news is that basketball is still quite approachable in this aspect because basketball courts do not require a lot of space and money.

Unlike other sports that require plenty of space, basketball is relatively affordable when talking about the court. This is why neighborhoods that are not as well-off as other places still have basketball courts. However, the good news is that, even though basketball courts can be expensive, you can still build one fairly cheap. And that is what we are here to talk about.

And that is what we are here to talk about.

I. How to Build a Basketball Court

II. How Much Does it Usually Cost to Build a Basketball Court?

III. 5 Things to Consider When Building a Basketball Court

IV. What’s the Cheapest Way to Build a Basketball Court?

V. Wrapping Things Up: How to Make a Basketball Court Cheap

How to Build a Basketball CourtBasketball is one of the most popular sports in the world. In most cases, people love the sport because of how fast-paced and exciting it is compared to other sports. However, some people play basketball because it is much more approachable and convenient than other sports. That is because the most important aspect of basketball is the hoop itself.

Even though you can play basketball with only a hoop, it still is better to play the sport on a real court because that will allow you to play with more people in a much more competitive environment. So, in that case, you might want to build a DIY basketball court for your personal use or the entire community. But how do you build a basketball court? We will show you a step-by-step guide on constructing a basketball court.

But how do you build a basketball court? We will show you a step-by-step guide on constructing a basketball court.

1. Location

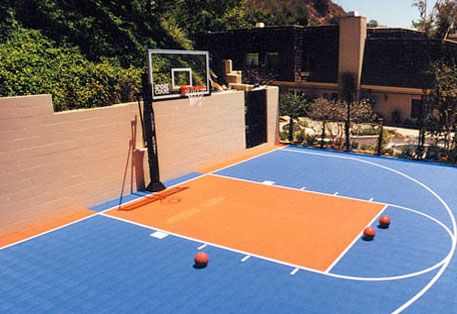

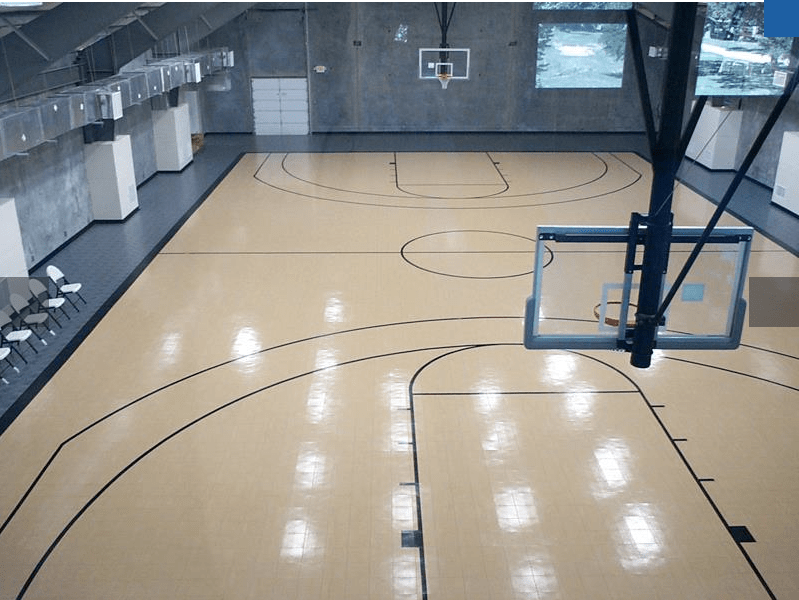

The most important part about building a basketball court is choosing the right location. It could be your backyard or a property you bought in your neighborhood. And if you live in a big city, you can even construct the court on a rooftop, which is quite common in some of the biggest urban areas in the world.

Regardless of where you choose to build your basketball court, it is equally important to choose the right size for the court. One of the best parts about building a basketball court is choosing between a half court or a full court. Half courts are better for smaller lot areas and 3-on-3 streetball setups. Meanwhile, full courts take up more space and are better when you want a taste of the real basketball experience.

Finally, about the location, it is best to choose a flat location because basketball is played on a flat surface. If the floor is slightly angled, the ball will bounce differently while dribbling it. That is why you should choose a location that is smooth and flat.

If the floor is slightly angled, the ball will bounce differently while dribbling it. That is why you should choose a location that is smooth and flat.

2. Size

Choosing the size of the basketball court you are planning to build depends on the size of the location. If you have enough space, you can choose to build a FIBA regulation-sized court, which is 91.9 by 49.2 feet or 28 x 15 meters. An NBA regulation-sized court is even bigger because it measures 94 by 50 feet. However, FIBA and NBA full-sized courts are too big for most backyards. You might be able to build a full-sized court if you own a big enough property.

But for those planning to build backyard basketball courts, you can build a half-sized court that is exactly half the measurements of a FIBA or NBA regulation-sized court. If that is still too big for your backyard, you can go with a very small court around 258 square feet. Meanwhile, the bigger 3×3 courts are 49 by 36 feet.

3. Flooring

When you already have the location and size of your basketball court decided, you may want to decide on the type of flooring you want to use for it. The most common type of flooring is concrete because it is very durable and long-lasting. Some people also claim that they perform well on concrete. Of course, concrete is the easiest and most affordable flooring you can choose.

The most common type of flooring is concrete because it is very durable and long-lasting. Some people also claim that they perform well on concrete. Of course, concrete is the easiest and most affordable flooring you can choose.

On the other hand, you can also choose hardwood, which most indoor basketball court floors are made of. But wooden basketball courts tend to be more expensive. On top of that, it is more difficult to maintain wooden basketball courts, especially if you plan to construct an outdoor court exposed to the elements. It should be better for you to choose a concrete court. Of course, you can also use pavers or asphalt.

4. Level the ground and pour the concrete

Before you pour the concrete on the floor, you must level the ground first. That is because basketball requires that you play on a smooth and even surface. Anything other than smooth and even flooring will make your experience less than ideal. It is best to dig around 100 millimeters into the ground.

After excavating, the next thing you should do is pour the concrete on top of the excavated ground. But you have to install the hoop anchor before you pour the concrete because the anchor is important when installing the hoop itself.

5. Install the hoop

Make sure that you buy a basketball hoop set instead of constructing your own. The reason is that pre-made basketball hoop sets are already measured according to standards. On top of that, there is no longer a need for you to make the measurements yourself.

Depending on where you bought your basketball hoop, it is best to ask the help of at least three people because this may require a bit of work on your part, especially if you consider that basketball hoops can be heavy. Make sure that you know the proper location to install the hoop. Again, the location will depend on the hoop you bought, as some hoops may need to be placed in different locations.

6. Paint the lines

Of course, a basketball court would not be complete without the lines that mark the different spots on the court. You may want to buy a basketball court line marking kit and use some chalk, masking tape, and measuring tapes for the job. And the most important part here is for you to study and know the regulation of basketball court dimensions to know where to paint the lines.

You may want to buy a basketball court line marking kit and use some chalk, masking tape, and measuring tapes for the job. And the most important part here is for you to study and know the regulation of basketball court dimensions to know where to paint the lines.

Here are some of the most important things to take note of here:

- The free-throw line is exactly 15 feet from the center of the hoop. Do not measure from the pole but from the center of the ring itself.

- The painted area or the lane is 12 by 19 feet.

- If you are building a full-sized court, you need to paint the center line exactly at the halfway point of the court.

Once you have all those covered, your basketball court is now ready for hoops!

How Much Does it Usually Cost to Build a Basketball Court?Building a basketball court is not a cheap endeavor because the construction materials you will be using will cost a lot of money. However, the overall expenses will depend on the type of materials you will use and on the size of the basketball court.

However, the overall expenses will depend on the type of materials you will use and on the size of the basketball court.

If you’re planning to build a court in your backyard, the good news is that the cost to build an indoor basketball court at home is minimized because you no longer need to buy a separate lot for the court. A half court will require you to shell out somewhere between $10,000 to $30,000, depending on the materials and the size.

However, if you want to build a bigger full court in your backyard (as long as you have enough space), you might want to spend around $60,000 to $80,000. In short, a full-sized court is going to be expensive.

Meanwhile, for those who want to build a court elsewhere, you might spend north of a hundred grand because you will also spend for the lot you will be building the court on. This should not be a problem if you plan to make a business out of the court. But if you are on a budget, especially if the court is for personal or community use, you have to make sure that you have enough money for this endeavor.

5 Things to Consider When Building a Basketball CourtWhen building a basketball court, here are the five factors that are important to consider:

1. Size

The size of the court is important because this will change the way you play on your court. Smaller courts are made for layups and shorter midrange shots, while full-sized courts are based on scrimmages and pickup games.

2. Flooring

Choosing the right flooring is essential because you need it to stand the test of time. Concrete is usually the best choice for a backyard court. If you want the concrete floor to be easier on your knees, you might want to cover it with sports court surface tiles, which will add more expenses to your total bill but are more than worth it.

3. Hoop

The hoop itself is the most important part of a basketball court because it will not be a basketball court without the hoop. There are plenty of ready-made hoop sets that come complete with the hoop anchors, pole, backboard, ring, and net. It is best to buy a ready-made hoop set instead of making your own to save time and effort.

It is best to buy a ready-made hoop set instead of making your own to save time and effort.

4. Line markings

The line markings are just as important as all of the other factors. Without the lines, it will be difficult to tell where you are shooting the ball from and whether or not you are already out of bounds.

5. Labor costs

Finally, it is important to consider the overall labor costs of building a basketball court. You might be able to save up on labor expenses by doing all of the labor yourself, but that will only take up a lot of time, especially if you do not have the background for this job. That is why you might want to hire laborers instead. Most laborers will charge around $300 to $400 a day.

What’s the Cheapest Way to Build a Basketball Court?As you can see, basketball courts are not cheap. Building one will cost you a lot of money, even though basketball courts are cheaper than some other sports courts. Still, the fact remains that basketball court costs are high. But the good news here is that you can minimize your costs for the cheapest way to build a basketball court.

But the good news here is that you can minimize your costs for the cheapest way to build a basketball court.

If you want to minimize expenses, the best way is to build a half court right in your backyard. Building anything bigger than a half court will cost you a lot of money. And making the court as small as possible without sacrificing the overall experience is a good idea. A court around 16 by 20 feet should already be spacious enough for most backyard half courts.

Next up, make sure that you use concrete for your flooring because this is the most affordable flooring you can use. If you want to minimize costs, forget about using sports court surface tiles. But concrete is not the easiest flooring for the knees and joints. Still, we are trying to minimize costs here.

Finally, it might be best to go with a wall-mounted hoop instead of one mounted on a pole. Wall-mounted hoops are cheaper and do not require more work and labor expenses because there is no need to install them on the floor. But you have to make sure that you build the court such that it faces towards the house so that you can mount the hoop on your home’s wall.

But you have to make sure that you build the court such that it faces towards the house so that you can mount the hoop on your home’s wall.

Wrapping Things Up: How to Make a Basketball Court CheapAll that said, building a basketball court is not cheap. Basketball courts may be some of the most affordable courts compared to other sports courts. However, the fact that there are still many construction factors that you need to consider means that you still have to spend a hefty sum for your court. And all you can do is minimize the expenses instead of going for a generally cheap court if you do not want to compromise the quality and experience.

Did you enjoy this post? Then you’ll love the other basketball 101 posts. Check them out below:

> How Many Square Feet is a Basketball Court?

> How Many Yards is a Basketball Court?

> How Many Laps Around a Basketball Court is a Mile?

Construction of a turnkey basketball court|SportObject

The SportObject company offers its services in the construction of turnkey basketball courts. Trusting the construction of our company, you get a whole range of turnkey services, including design, ground work, laying the base and coating, marking and other construction work. We strictly adhere to the agreed deadlines and provide our clients with a work schedule that indicates the start and completion dates for construction.

Trusting the construction of our company, you get a whole range of turnkey services, including design, ground work, laying the base and coating, marking and other construction work. We strictly adhere to the agreed deadlines and provide our clients with a work schedule that indicates the start and completion dates for construction.

Find out why it is safe to cooperate with us

Details

Calculation of the cost of the object

To find out the estimated cost of your object, select the options below or use the detailed calculator available by clicking the "Make a detailed calculation" button.

1. Coating:

Choose the type of coating for your object.

Not selectedAcrylicRubber crumbModular plasticPolyurethane

2. Destination:

Specify where your object will be used.

Not selectedFor suburban developmentsFor educational institutionsFor competitionsFor sports organizationsFor private business

3. Your object:

Your object:

Specify whether your object is located: indoors, outdoors or it needs a hangar.

Not selectedOutdoor (outdoor)Indoor (indoor)To be built (prefabricated hangar)

4. Field sizes:

Select the appropriate field size from the list provided.

Not selectedCustomStandard30x18 - (playing dimensions 28x15) 34x19 - for competitions (playing dimensions 28x15)

Specify the parameters of your object in a detailed calculator and get an approximate cost of the service.

Budget savings

We help reduce your costs by up to 40% and avoid unnecessary overpayments.

3 day project

We will design and calculate the exact cost of your object in just 3 days.

5 year warranty

We give great guarantees for imported goods and materials from our warehouse.

421 590* 421590 RUB

* The price is indicated for the basic package with a coating without a base. You can also use the detailed calculator.

Implementation example

Private sector basketball court

Difficulty:

Rubber slabs for outdoor sports grounds are perhaps the most reliable and rational option of all. The coating is made of high-strength crumb rubber and a binding polymer (polyurethane adhesive).

More

Get a consultation

Order a call back and one of our managers will advise you on all your questions

You can also call

8 (495) 240-82-24

By submitting your personal data through the forms on the site, you give your consent to the processing of personal data in accordance with Federal Law No. 152-FZ "On Personal Data" dated July 27, 2006, as amended on July 1, 2017.

152-FZ "On Personal Data" dated July 27, 2006, as amended on July 1, 2017.

Stages of construction on the example of a football stadium

The thickness of the foundation pit and the amount of materials that are needed for your foundation, we select depending on the size of the field. We select drainage and other systems based on the regional location (how much precipitation is in your region, what kind of drainage is needed). Additionally, we equip drainage wells, or divert them to the drainage system. Field slopes of several different types depending on site operating conditions.

Preparing the excavation, sand bed, drainage system

The quality of a football field is more than half dependent on the quality of the base! Our base is a monolithic solid single layer, which over the years does not form any fractures, the soil does not go anywhere and remains flat throughout the entire period of operation. Relatively speaking, even if a tractor passes over the base, there will be no tire marks, because everything is solid and dense!

Sequential compaction of base layers

We carry out all types of additional improvement works: we can install a fence for you, pave an asphalt path to something, level the territory, paint walls, curbs, etc. We will perform all the required related work!

We will perform all the required related work!

Installation of the curbstone

The laying of artificial grass itself is as important as the preparation of the base. When laying the field, an important aspect is gluing the rolls and cutting the markings. Gluing must be done securely. The material in the work requires getting used to, because the two-component glue rolls down after a while and they need to work quickly.

Laying the grass on the prepared base, gluing it and cutting the markings

Be sure to remember: the gate is installed with a safety requirement so that it does not turn over. Therefore, this aspect is given special importance. In this regard, the gate is either concreted or attached to an accompanying fence.

Installation of the goal

The backfilling of a football field determines a large part of the playing characteristics. Backfilling is a responsible job, because the presence or absence of drops and bumps, which will eventually be felt during the game, depends on the uniform distribution of sand and crumb rubber on sports grounds. That is, there should be both a flat base and a high-quality pile with an even distribution of backfill under it.

That is, there should be both a flat base and a high-quality pile with an even distribution of backfill under it.

Raising grass, distributing sand and crumb rubber across the field

We cooperate with the largest manufacturers of stands, fences and other sports equipment in the Russian Federation. Therefore, if necessary, we can supply everything you need to the object at a wholesale price. We install all this equipment, advise in which cases which is better, etc. We can supply many things both in a finished version and make them ourselves on the spot.

Installation of additional equipment (treadmills, jumping pits, safety fences, grandstands)

You can also be sure that we will carry out all the necessary arrangements for their improvement on the site and the adjacent territory.

Landscaping

The thickness of the foundation pit and the amount of materials that are needed for your foundation, we select depending on the size of the field. We select drainage and other systems based on the regional location (how much precipitation is in your region, what kind of drainage is needed). Additionally, we equip drainage wells, or divert them to the drainage system. Field slopes of several different types depending on site operating conditions.

Additionally, we equip drainage wells, or divert them to the drainage system. Field slopes of several different types depending on site operating conditions.

Preparing the excavation, sand bed, drainage system

The quality of a football field is more than half dependent on the quality of the base! Our base is a monolithic solid single layer, which over the years does not form any fractures, the soil does not go anywhere and remains flat throughout the entire period of operation. Relatively speaking, even if a tractor passes over the base, there will be no tire marks, because everything is solid and dense!

Sequential compaction of base layers

We carry out all types of additional improvement works: we can install a fence for you, pave an asphalt path to something, level the territory, paint walls, curbs, etc. We will perform all the required related work!

Installation of the curbstone

The laying of artificial grass itself is as important as the preparation of the base. When laying the field, an important aspect is gluing the rolls and cutting the markings. Gluing must be done securely. The material in the work requires getting used to, because the two-component glue rolls down after a while and they need to work quickly.

When laying the field, an important aspect is gluing the rolls and cutting the markings. Gluing must be done securely. The material in the work requires getting used to, because the two-component glue rolls down after a while and they need to work quickly.

Laying the grass on the prepared base, gluing it and cutting the markings

Be sure to remember: the gate is installed with a safety requirement so that it does not turn over. Therefore, this aspect is given special importance. In this regard, the gate is either concreted or attached to an accompanying fence.

Installation of the goal

The backfilling of a football field determines a large part of the playing characteristics. Backfilling is a responsible job, because the presence or absence of drops and bumps, which will eventually be felt during the game, depends on the uniform distribution of sand and crumb rubber on sports grounds. That is, there should be both a flat base and a high-quality pile with an even distribution of backfill under it.

Raising grass, distributing sand and crumb rubber across the field

We cooperate with the largest manufacturers of stands, fences and other sports equipment in the Russian Federation. Therefore, if necessary, we can supply everything you need to the object at a wholesale price. We install all this equipment, advise in which cases which is better, etc. We can supply many things both in a finished version and make them ourselves on the spot.

Installation of additional equipment (treadmills, jumping pits, safety fences, grandstands)

You can also be sure that we will carry out all the necessary arrangements for their improvement on the site and the adjacent territory.

Landscaping

Options

How do we work?0003

We carry out construction and installation works

We hand over the finished object and provide a guarantee

Private

I am a private client

We work in all regions of the Russian Federation

We cooperate with contractors who are ready to travel to any city in Russia. We take measurements, bring materials or buy them in your city, install coatings and equipment.

We take measurements, bring materials or buy them in your city, install coatings and equipment.

We offer standard solutions

We are engaged in the construction of both standard and unique projects. We work individually with each client: we take into account your wishes, fit into the budget and comply with the agreed deadlines.

We take care of your budget

We help clients in the selection of materials, places for construction, provide detailed advice and suggest how to get a fully functional sports facility at a lower cost.

We create 3D visualization

We offer the development of a 3D model that will convey a complete vision of the concept of the future object. Also, this service will help both us and the client to eliminate the possibility of error at the design stage.

We make reconstruction and repair

We carry out all types of reconstruction works: we repair the foundation, lay the foundation, replace the coatings, install fences, roof structures, make glazing and ennoble the areas.

I am a frequent customer

Corporate

I am a corporate client

We offer additional services

We are engaged in maintenance of the facility after commissioning: we take care of the condition of sports surfaces, ennoble areas, do glazing and other general construction works.

We take on complex projects

We have enough experience and capabilities to solve the most non-standard and complex tasks. Many of our specialists took part in the preparation of sports grounds for the Olympic Games in Athens and the 2018 World Cup.

We cooperate with global companies

We maintain strong partnerships with well-known manufacturers from Europe and Asia. At the request of the customer, we supply the goods you like from abroad in the shortest possible time.

We provide detailed advice

We answer in detail all the client's questions about the project and our services. Also, we are ready to provide professional legal advice on construction issues.

We build turnkey facilities

We provide a whole range of services: designing an object, drawing up design estimates, building a foundation and base, selecting and laying coatings, erecting roofed structures, installing appropriate equipment and necessary communications.

Our clients

I am a corporate client

Acknowledgments and certificates of conformity

Company "SportObject" offers its services in the field of sports construction. We are engaged in the construction of turnkey basketball courts: we design, draw up design estimates, coordinate the construction, mount the foundation and roof structures, lay bases and coverings, perform finishing work, provide communications and deliver sports equipment. Each of the stages of work is implemented strictly according to the schedule agreed with the client, which allows us to deliver a fully finished project on time.

We are engaged in the construction of turnkey basketball courts: we design, draw up design estimates, coordinate the construction, mount the foundation and roof structures, lay bases and coverings, perform finishing work, provide communications and deliver sports equipment. Each of the stages of work is implemented strictly according to the schedule agreed with the client, which allows us to deliver a fully finished project on time.

We value the trust of each customer and guarantee comfortable cooperation

- We travel to any place in Russia;

- We provide detailed advice on construction issues;

- We select high-quality solutions for the client's budget;

- We help with the choice of an advantageous place for construction;

- We work with complex and non-standard ideas;

- We offer creative solutions within a reasonable budget;

- We provide additional facility maintenance in other regions of Russia.

We supply basketball surfaces from world manufacturers

The dynamics of basketball matches means high speed, sudden movements and heavy loads on the joints. It is very important that the flooring of the basketball court is both wear-resistant and injury-proof at the same time. For basketball courts we offer: tennis, hard or soft-hard, modular plastic, polyurethane coating and crumb rubber coating.

It is very important that the flooring of the basketball court is both wear-resistant and injury-proof at the same time. For basketball courts we offer: tennis, hard or soft-hard, modular plastic, polyurethane coating and crumb rubber coating.

Our company only works with proven materials that have passed the strictest quality control, so we offer a wide selection of outdoor basketball surfaces from domestic and foreign manufacturers, such as: ERFOLG , BERGO , Plastfacto , Conica , Novol , Aropa , CRUMB , GUMBIT 90 MASTER FIBER and many more.

In addition to the construction of basketball courts, we take care of the complete set of the object and provide it with all the necessary equipment until it is ready for operation. In accordance with the requirements of the customer, any sports equipment can be installed: backboards, rings, stands of a certain capacity, running tracks, a sector for standing long jumps and, of course, various types of fences.

We offer metal fences or safety nets at the customer's choice

- Metal 2D and 3D railings are sectional structures of increased strength with rod diameters from 4 to 6 mm, protected by a polymer and zinc coating. Unlike other fences, mesh panel fencing is maintenance-free - it does not collect dust, does not fade in the sun and does not deform under wind loads, and also does not need periodic painting

- Protective mesh made of kapron or nylon threads can have different mesh sizes: 100x100, 40x40 or 20x20. Such a fence is ideal for zoning the playing space and protecting spectators from sports equipment. The mesh does not need maintenance and is easily restored

While building new basketball courts, we also work on existing facilities that need major repairs or minor restoration. We are happy to undertake the design of a sports facility, without including construction work, and for the implementation of the facility according to an already finished project.

You can ask us a question, leaving your contact details. We will call you back shortly.

You can also call

8 (4

Basketball court cover for sale

Basketball court cover for sale Construction of an indoor basketball hall requires a lot of labor, materials and design. The basketball court surface can be built on an existing basketball court, which is a great advantage of this temporary construction.

We have over 20 years of professional experience. This outdoor basketball court surface took only 15 days from design, production, transportation and construction to operation, which is incomparable with traditional architecture.

During the construction process, the basketball court surface significantly reduces labor costs. The material is accurate to the centimeter, it is more economical than traditional buildings in terms of value for money. In addition, there is no construction waste, and it can be recycled and reused, which is more in line with the concept of sustainable building.

Although this is a transformation of an outdoor basketball court, LIRI places rather high demands on the functional equipment of a basketball court. The special wooden floor for basketball courts used inside not only has elasticity, but also has good anti-slip performance, which can meet the needs of professional basketball games.

As a professional all-weather basketball stadium, the basketball court surface with a side height of 6m is made of PVC coated double membrane, and the inner layer is designed with a thermal insulation layer, which has excellent waterproof and blocking performance. We also take into account the factors of heavy snowfall in winter, and horizontal steel wires are specially added inside the roof to resist snow.

Considering the comfort of being inside, the basketball court surface can also be equipped with electrical equipment, and the court has a large number of LED lights designed for various sports, which makes it available also for training or basketball competitions at night.