Home »

Misc »

How much for asphalt basketball court

How much for asphalt basketball court

How Much Does It Cost to Build a Basketball Court in Your Yard?

Typical Range:

$11,000 - $76,000

Cost data is based on research by HomeAdvisor.

Updated May 26, 2022

Reviewed by Robert Tschudi, Expert Home Building and Remodeling Contributor.

Written by HomeAdvisor.

If you love shooting hoops, building a custom basketball court may be well worth it. The national average cost to build a basketball court is $35,000. On the highest end of the spectrum, you may pay up to $76,000, or as low as $11,000. Several factors influence the final price tag—including size, materials, and labor—and it’s important to be aware of these before you start this project.![]()

In this article

- Half vs. Full Basketball Court

- Indoor vs. Outdoor Court Costs

- Outdoor Basketball Court Cost Factors

- Indoor Basketball Court Cost Factors

- Additional Basketball Gym Options

- Budget-Friendly Alternatives

- FAQs

Half vs. Full Basketball Court

Most homeowners will need to install a half-court since not many homes can accommodate a full-sized basketball court. A half-court of 47 by 50 feet (or 2,530 square feet) generally costs from $8,600 to $38,000. A smaller court of 30 by 30 feet (or 900 square feet) costs between $3,300 and $15,000.

If you have the space available, a full-sized court that measures 94 by 50 feet (or 4,700 square feet) runs from $17,200 to $76,000.

Full Court

Many people prefer the NBA/NCAA standard size (which is 97-by-50 feet), but smaller full courts are common. When considering sizes, remember to add a few extra feet for the perimeter.

| Standard | Dimensions | Average Cost |

|---|

| NBA/NCAA | 97’ x 50 | $46,000 |

| 10x10 | 84’ x 50 | $41,500 |

| 11x11 | 74’ x 42’ | $31,000 |

Half Court

Half-court dimensions are typically 47-by-50 feet for the pros. That’s the size that most homeowners opt for if they have the space for it.

| Standard | Dimensions | Average Cost |

|---|

| NBA/NCAA | 47’ x 50’ | $23,000 |

| High School | 42’ x 50’ | $21,000 |

| Junior High | 37’ x 42’ | $15,500 |

| 3-on-3 Court | 30’ x 30’ | $9,000 |

Indoor vs.

Outdoor Court Costs

Installing an indoor basketball court will cost you anywhere from $16,650 to $70,700, depending on your material choices and labor costs. If you already have a designated structure or area for an indoor court, that will reduce the overall expense.

Installing an outdoor court is generally more complex and time-consuming than installing an indoor court. You can expect to pay $17,200 to $76,000 to build an outdoor court.

Find a Basketball Flooring Pro Near You

ZIP Code

Find a Pro

Outdoor Basketball Court Cost Factors

Installing a court in your backyard gives you more flexibility in terms of placement and installation. Prices vary based on the material used and the amount of prep work. You can expect to pay about $4 to $16 per square foot, or $17,200 to $76,000, for a standard size.

| Outdoor Court Options | Low | High |

|---|

| Flooring | $14,000 | $45,000 |

| Land Leveling | $1,300 | $4,500 |

| 11x11 | $1,900 | $5,000 |

Material

Putting in concrete for an outdoor sports surface is similar to the price of installing a concrete patio. Poured concrete costs $1.25 to $1.75 per square foot for materials and $2.50 to $8 per square foot for installation, totaling $15,000 to $45,000 for a full size court. Some homeowners prefer to install an asphalt driveway to accommodate a basketball court. The cost of placing asphalt is usually around $3 to $4 per square foot or $14,000 to $18,000 for a full court.

Poured concrete costs $1.25 to $1.75 per square foot for materials and $2.50 to $8 per square foot for installation, totaling $15,000 to $45,000 for a full size court. Some homeowners prefer to install an asphalt driveway to accommodate a basketball court. The cost of placing asphalt is usually around $3 to $4 per square foot or $14,000 to $18,000 for a full court.

Other options for an outdoor court base include snapping tiles and a portable base. Expect to pay between $3.50 and $4.50 per square foot for pre-painted tiles, which totals $17,000 to $22,000 for a full court and $3,2000 to $4,100 for a 3-on-3. A portable base is a good option if you can’t have a permanent outdoor base. Products like SportBase or UltraBase Systems are often higher in price than concrete when it comes to materials, though they have lower installation costs.

Size

Sizing is a major factor in the cost breakdown. A full-sized court costs between $17,200 and $76,000, while a half-court costs between $8,600 to $38,000.

Labor

Labor costs generally range from $13,000 to $40,000. Preparing the outdoor court site can be time-consuming and labor-intensive, as it involves excavating and leveling the land, prepping for drainage, and installing the court surface and all the features.

Land Leveling

You’ll need a perfectly even surface for your basketball court, which generally entails leveling the land or adjusting the slope of your backyard. The average cost to level a yard is $2,100 depending on the project’s complexity. Resloping your lawn costs around $2,000 per project.

Drainage

You’ll also need proper grading to avoid flooding the court surface or your home. The cost to install a yard drainage system is $4,000 on average.

Lighting

You may also want to install lighting for night games. Expect to pay $1,500 for a comprehensive low-voltage outdoor lighting system.

Fencing

Installing a fence to block stray basketballs costs around $13 to $50 per linear foot, depending on the material.

Painting

Installing goals and painting lines adds about $800 to $2,400.

Additional Landscaping

You may need to remove bushes, shrubs, or trees to make room for the basketball court. On average, removing bushes and trees costs $880, with most homeowners paying between $430 and $1,340. These prices reflect total project costs.

Additional Accessories

You’ll also need to take into account the price of installing a basketball hoop, which will vary depending on the structure. The cost of the hoop generally ranges from $300 to $1,600, plus about $450 for installation.

Hire a Contractor to Build Your Backyard Basketball Court

ZIP Code

Get Estimates Now

Indoor Basketball Court Cost Factors

When it comes to installing an indoor basketball court, flooring and labor are your two biggest expenses. If you need to extend the square footage of your space, remodel your basement, or add ventilation or ductwork, be sure to factor in these renovation expenses, too.

If you need to extend the square footage of your space, remodel your basement, or add ventilation or ductwork, be sure to factor in these renovation expenses, too.

Flooring Material

The standard choice for most indoor courts is maple hardwood, which costs around $3.50 to $6 per square foot for the wood, plus another $3 to $8 per square foot for installation. On a full-sized court, the cost of hardwood flooring would total $29,000. For a 3-on-3 court, the cost would be about $5,500.

Alternatively, if you like the look of maple hardwood but want a more affordable material, laminate is a great option. Putting in laminate flooring costs a fraction of hardwood—expect to pay just $0.70 to $2 per square foot for materials and $2 to $8 per square foot for installation. Laminate on a full court runs about $13,000 to $47,000 in total, and it’s $2,500 to $9,000 for 3-on-3 sizing.

Size

The size of the court has a big impact on the final cost. A full-sized court costs between $17,200 and $76,000, while a half-court costs between $8,600 to $38,000.

A full-sized court costs between $17,200 and $76,000, while a half-court costs between $8,600 to $38,000.

Labor

Labor costs vary depending on the size of the court and flooring type. Get in touch with your local contractor to request a price quote for their hourly labor costs.

Painting

Painting court markings can add about $800 to $2,400 to the final project cost, but you can easily DIY this task. A one-gallon can of paint is about $30 to $40.

Soundproofing

The cost of soundproofing a room typically ranges from $1,100 to $2,750, averaging $1,880. Some cost factors include the size of the room and the degree of soundproofing that you require.

Ventilation

You can expect to pay around $1,100 to add ventilation or ductwork to an indoor basketball court.

Lighting

Lighting fixtures are necessary for all indoor basketball courts. Depending on the complexity of the installation, expect to pay between $450 and $550 per fixture.

Additional Accessories

Be sure to factor in any extra features, upgrades to premium materials, and other sports equipment. A standard-sized hoop costs around $300 to $1,600.

Additional Basketball Gym Options

You may decide to build an additional home gym to complement your basketball court. The cost of this project will depend on the type of structure: an attached addition, a detached addition, or a pole barn.

Attached Addition

Installing an attached addition costs between $80 and $200 per square foot. You may pay as much as $43,000 for the whole project, depending on the size of the space and structural details.

Detached Addition

The cost of installing a detached addition is similar to the cost of building a detached garage, which is about $27,000 per project. Expect to pay more for larger additions.

Pole Barn

A pole barn is a type of post-frame construction, and it’s generally the most affordable addition option. You can expect to pay $8,000 to $20,000 for a pole barn measuring 30 to 40 feet.

You can expect to pay $8,000 to $20,000 for a pole barn measuring 30 to 40 feet.

Budget-Friendly Alternatives

If you’re installing a basketball court on a budget, consider using laminate flooring instead of maple hardwood.

You could also tackle some of the easier installation tasks yourself, such as painting your own court markings instead of hiring a professional painter. Buying your own materials—including rollers, pads, trays, primer, paint, and tape—may set you back anywhere from $50 to $100. Meanwhile, it’ll cost anywhere from $200 to $6,000 to hire a professional painter.

FAQs

How many square feet is a basketball court?

A standard full-sized basketball court runs 94 by 50 feet. A half-size court is 47 by 50 feet.

How much does it cost to hire someone to install a basketball hoop?

It will cost about $450 to hire a professional to install a basketball hoop. Keep in mind that the cost of the hoop ranges from $300 to $1,600, depending on its size and quality.

What does it cost to resurface or refinish an outdoor sports court?

You may need to repair or refinish your outdoor area to allow for a smooth surface. Repairing concrete is about $300 to $3,500 per project, depending on the extent of the damage. Resurfacing asphalt costs $2,900 on average.

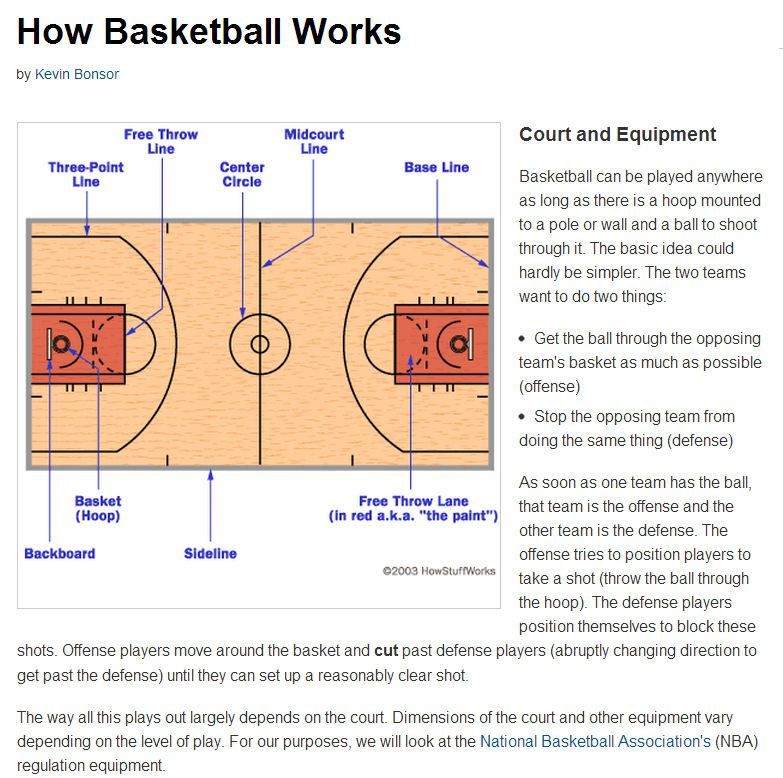

How do you paint basketball lines on concrete, asphalt, or hardwood?

Once you have the proper base and surface for your basketball court, you’ll need to paint the court markings. You can either hire a professional painter for this task, or you can paint the basketball lines yourself. Hiring a pro costs about $300 for basic markings. Be sure to use acrylic paint for concrete or asphalt outdoor courts, and a fast-drying water-based paint for hardwood indoor courts.

Find a Basketball Flooring Pro Near You

ZIP Code

Find a Pro

Related Projects Costs

- Build or Resurface a Tennis Court

- Repair a Tennis Court

- Refinish Hardwood Floors

- Install Wood Flooring

- Install Laminate Flooring

- Coat Concrete With Epoxy

- Build an Addition

- Install Stamped Concrete

- Install Asphalt Paving

- Seal Asphalt Paving

Find Pros Nearby

- Basketball Hoop Assembly Services Near You

- Cement Companies Near You

- Home Remodelers in Your Area

- Local Asphalt Companies

- Nearby Tennis Court Installers

- Playground Installation Pros in Your Area

Photo: Iriana Shiyan / Adobe Stock

Popular Categories

- Additions & Remodels

- Bathrooms

- Heating & Cooling

- Kitchens

- Landscape

- All Categories

Popular Projects

- Hire a Handyman

- Hire a Maid Service

- Install Landscaping

- Remodel a Bathroom

- Remodel a Kitchen

Featured Articles

- How Much Does it Cost to Install or Replace Kitchen Cabinets?

- How Much Does a Home Addition Cost?

- Install Countertops

- How Much Does it Cost to Install a Window?

- How Much Does It Cost to Clean Gutters?

Find Tennis or Game Court Builders & Resurfacers Near You

- Miami, FL

- Charlotte, NC

- San Antonio, TX

- Fort Lauderdale, FL

- Las Vegas, NV

- Los Angeles, CA

- West Palm Beach, FL

- Winston Salem, NC

- Austin, TX

- Riverside, CA

- Louisville, KY

- Fort Worth, TX

- Albuquerque, NM

- Raleigh, NC

- Phoenix, AZ

- New York, NY

- Minneapolis, MN

- Durham, NC

- Chicago, IL

- Salt Lake City, UT

- Saint Paul, MN

- Rochester, NY

- Richmond, VA

- Norwalk, CT

- Meridian, MS

- Littleton, CO

- Kearney, NE

- Kansas City, MO

- Houston, TX

- Fayetteville, NC

- Alexandria, LA

- Greensboro, NC

- Grand Rapids, MI

- Flushing, NY

- Eugene, OR

- Dover, DE

- Dallas, TX

- Birmingham, AL

- Arlington, VA

- Anchorage, AK

Don't see your city?

Cost of a Backyard Basketball Court

Cost of a Backyard Basketball Court

- Angi

- Solution Center

- Outdoor Living

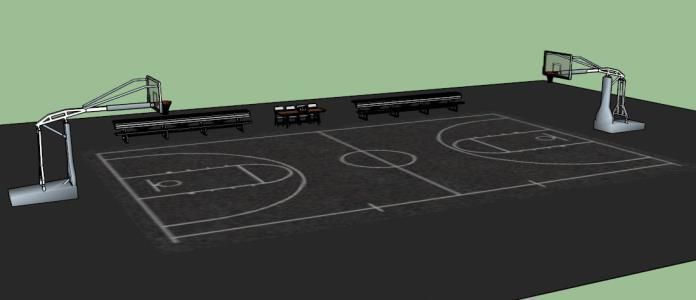

Photo: Image by Marie LaFauci / Moment / Getty Images

Highlights

$8,600 to $75,200 is the average cost range for an outdoor basketball court.

Required labor to install a court can significantly impact costs.

DIY installation isn't advisable for most people; it's a labor-intensive job.

Get quotes from up to 3 pros!

Enter a zip below and get matched to top-rated pros near you.

For those who believe “ball is life,” having your own basketball court is a dream come true. If you’re looking to turn your backyard into an at-home NBA court, the price tag starts at $8,600 and can reach $75,200, depending on several factors.

Outdoor Basketball Court Cost Breakdown

Many factors affect the cost of installing an outdoor basketball court.

Size of the Court

The larger the court, the more it will cost. The size of the court has a big impact on final costs. A full-size basketball court is 94-by-50 feet, or 4,700 square feet. Depending on the amount of land you have to dedicate to b-ball (and your budget) you can opt for a half-court to save on costs.

Generally, building an outdoor basketball court will cost you between $4 to $16 per square foot. You’ll reach the higher end of the range if you opt for premium materials or need to do some grading to prep the site before you build.

| Type | Cost |

|---|

| Half Court | $8,600 – $40,000 |

| Full Court | $18,800 – $75,200 |

Land Condition

If the land you want to put the court on is bumpy and uneven, or there are drainage issues, you'll have to spend a lot of money on preparing the site. Yard grading costs $1 to $2 per square foot.

Labor

Labor is likely to be your biggest expense, potentially taking up the majority of your budget. Installing a basketball court is hard work with long hours. Labor costs can vary greatly depending on the region. The job size can also increase the overall cost of the labor. Courts take four to six weeks to build, so a full court might cost anywhere from $1,000 to $4,000 per day. Hourly rates likely won't apply, even for small courts.

Hourly rates likely won't apply, even for small courts.

A local tennis court company or service will bill similarly. A tennis court costs about $60,000 to build from scratch.

Base Materials

Most contractors will recommend concrete or asphalt for outdoor courts because traditional hardwood courts won’t withstand weather conditions.

The price of flooring will run from $14,000 to $45,000 for a full-sized outdoor court. You'll need to pour concrete, which costs $1.25 to $1.75 per square foot just for the materials, and another $2.50 to $8 per square foot for installation. Polymeric rubber is also an option, though can be more costly—up to $25 per square foot, in some cases.

| Type | Price |

|---|

| Asphalt (Half Court) | $9,400 – $28,000 |

| Asphalt (Full Court) | $8,700 – $56,400 |

| Poured Concrete (Half Court) | $8,812 – $22,912 |

| Poured Concrete (Full Court) | $17,625 – $45,825 |

| Rubber (Half Court) | $37,600 – $58,750 |

| Rubber (Full Court) | $75,200 – $117,500 |

Foundation

An outdoor court needs a concrete slab reinforced with rebar as a foundation. As a result, you will need to pour concrete prior to installing the court.

As a result, you will need to pour concrete prior to installing the court.

Drainage and Grading

To ensure the court’s hard surface is on flat land with proper drainage, you need a construction professional to do drainage and grading work. This cost varies greatly, from $3,200 to $9,500.

Hoop

A hoop is generally one of the more inexpensive parts of a basketball court, but it will still affect your budget as they can cost in the thousands. You can purchase portable basketball hoops online for as little as $50. But if you want a permanent, professional basketball hoop installed, you may spend as much as $2,000 per hoop, and $450 to have a local pro install it.

The materials you choose for the backboard could also drive the price up for your new hoop.

| Type of Hoop | Cost to Install |

|---|

| Standard | $50 – $250 |

| Portable | $140 – $5,659 |

| Acrylic | $1,750 – $4,360 |

| Polycarbonate | $290 – $2,000 |

| In-Ground | $400 – 1,600 |

Paint

It takes several gallons of paint to paint an entire basketball court. Lining a full court will cost $350 to $800. For concrete, there's a possibility you'll need to do two coats or reapply every couple years.

Lining a full court will cost $350 to $800. For concrete, there's a possibility you'll need to do two coats or reapply every couple years.

For nighttime hoopers or those who need to get a workout in before work, installing lights on your outdoor basketball court could be a good option. The number of lights you'll need will depend on the court size. A low-voltage system will start at around $1,500.

In addition to lights, you could add features like:

Bench seating

Scoreboard

Fencing

How Much Does It Cost to Install a Basketball Court Yourself?

Photo: Iriana Shiyan / Adobe Stock

If you have all the equipment needed to do the job, bought the materials yourself, and have people willing to help you out for free, you could probably construct the court for about $15,000 to $20,000.

DIY vs. Hiring a Pro

Unless you have extensive construction experience, you’re better off playing basketball than trying to build the court. DIYing a basketball court isn’t as simple as laying the groundwork—you need to level the land, ensure there’s proper drainage, and pour concrete.

DIYing a basketball court isn’t as simple as laying the groundwork—you need to level the land, ensure there’s proper drainage, and pour concrete.

It's best to pay professionals to ensure everything is done right—and, just like the game, this is a team effort.

How To Save Money Building a Basketball Court

Outside of taking a DIY approach—which requires a ton of work and is only for truly savvy homeowners—you can cut costs in a few ways. Here are some tips to save money when building a basketball court.

1. Consider a Garage or Driveway Hoop

Scaled-back options like these won't give you a full court in your home, but if hooping on a budget is your goal, they could be solid alternatives you can build faster.

Mounting a garage basketball hoop only costs under $100. With some paint, you can add a half-court set up on your driveway if space allows.

2. Do Renovation Projects Yourself

A poured concrete basketball court could be cheaper than a hardwood indoor court. You can save thousands by digging the space out yourself. Although difficult, digging a uniform four-feet deep hole for the area can be something you tackle slowly over a couple of months. Once finished, you can have a local concrete contractor lay concrete and paint the court yourself.

You can save thousands by digging the space out yourself. Although difficult, digging a uniform four-feet deep hole for the area can be something you tackle slowly over a couple of months. Once finished, you can have a local concrete contractor lay concrete and paint the court yourself.

FAQs About Outdoor Basketball Courts

Is it better to play basketball outdoors or indoors?

So long as your court and hoop dimensions are the same, any basketball player can get a great workout and improve their skills on an indoor or outdoor court. However, you might consider using or building an indoor court if you live in a particularly rainy or windy area, as this can make it difficult to play outdoors.

Should I build an outdoor basketball court myself?

It’s tempting to try to save money building an outdoor basketball court yourself, but the truth is laying the flooring requires heavy equipment and lots of labor. So it’s best to hire a professional to do the job.

How do I create an outdoor basketball court budget estimate?

If you want to know from the outset how much you’re likely to pay to install an outdoor basketball court, create a budget breakdown that lists the following expenses:

Labor: How many work hours will you need, and what is the average price of labor in your area?

Materials: What material do you plan to use, and what is the average price per square foot?

Drainage, grading, and laying cement slabs: Do you need to level or prep your area? Have a professional evaluate your property to determine what you will need to pay a contractor to do this work.

Hoops, lighting, fencing, painting lines, and other extras: What extras are non-negotiable? Create a list of all of the extras you want your court to have.

Why should I use asphalt for my outdoor basketball court?

Asphalt, which is stone mixed with tar, is the most common material for outdoor basketball courts because it’s so sturdy and versatile. However, you don't have to use it: another option is polymeric rubber, which has shock pads that can prevent injury. This option is a little more expensive, ranging between $16 and $25 per square foot.

However, you don't have to use it: another option is polymeric rubber, which has shock pads that can prevent injury. This option is a little more expensive, ranging between $16 and $25 per square foot.

Materials used for indoor basketball courts, such as hardwoods, aren’t really an option outdoors.

Need professional help with your project?

Get quotes from top-rated pros.

Recommended Articles

Asphalt for playgrounds and sports grounds - how to choose

Asphalt (asphalt concrete) is a material based on crushed stone, sand and bituminous binder. It is actively used both in road construction and in works on improvement and design of territories.

For example, it is used in the construction of:

- Playgrounds

- Sports fields

- Treadmills

- Stadiums

- Kortov

In these works, asphalt can perform various functions.

It is used as:

- Asphalt for playgrounds and sports grounds

- Asphalt at the base of children's and sports grounds

- Types of asphalt for the bases of children's and sports grounds

- Features of asphalting the bases of children's and sports grounds

- Soft coatings for asphalt for children's and sports grounds

- Asphalt pavement for sports fields

- How to choose asphalt for covering a sports field

- How to reduce the risk of asphalt injury

- Alternatives to asphalting children's and sports grounds

In this article we will talk about the features of the use of asphalt in both cases, its disadvantages and advantages. We will also consider the basic requirements for the material and give recommendations on its choice.

Asphalt in the base of children's and sports grounds

Today, modern soft materials based on rubber and polymers are actively used to cover playgrounds. Such popularity is dictated by their excellent operational properties and safety. After all, children, especially small ones, do not have good coordination. A fall on a hard surface can cause serious injury.

Such popularity is dictated by their excellent operational properties and safety. After all, children, especially small ones, do not have good coordination. A fall on a hard surface can cause serious injury.

But you can't put expensive flooring on bare ground. First you need to equip a reliable and even base.

It can be:

- Crushed stone and sand cushion

- Asphalt

- Concrete

Each of these options has its advantages and disadvantages, depending on different criteria.

They are shown in the table below:

For your convenience, we have placed this table below as a picture:

Let's recap:

- A compacted gravel and sand base is suitable for a small playground in an enclosed courtyard of a house or kindergarten. This is a quick and easy option that is suitable for areas with light traffic. But it may not be the most budgetary, because you have to spend more money on the topcoat.

- Asphalt base is the best option for sites that are designed for active use. These can be children's playgrounds, stadiums at schools and educational centers, city sports grounds and treadmills.

- Strong and durable concrete bases are suitable for stadiums and sports arenas, playgrounds in city parks. You can take this material for less responsible work. But keep in mind that pouring will take more time and effort than laying asphalt. And you will have to take care of the base for a few more days: keep it under a film and water it periodically.

In the next section, we will discuss in more detail which types of asphalt are used in this kind of work.

Types of asphalt for foundations of children's and sports grounds

There are no strict requirements for the quality of asphalt in landscaping. After all, this is not the main scope of the material. Purely technically, you can use any of its varieties.

But there are other criteria such as convenience and expediency. They dictate real building practice.

They dictate real building practice.

When choosing an asphalt mix (ABS), consider the following:

- Paving method

Hot asphalt laid at temperatures above 100°C is the best choice. This is a versatile material that is suitable for almost all jobs. In times of austerity, you can take asphalt cutting, but it's risky. It is not certified, and no one guarantees its quality. It makes no sense to take cold and cast asphalt - they are expensive and have no special advantages in such work. - Porosity

The proportion of air voids in the material must not exceed 10%. This requirement is met by high-density, dense and porous asphalts. Moreover, the denser the coating, the better it resists destruction by water and ice. - Grain size

Fine-grained (filler size - up to 20 mm in diameter) or sandy (up to 5 mm) mixtures are taken for arranging the bases, since they can be laid even without the involvement of heavy equipment.

- Type (crushed stone content)

Crushed stone in the composition of asphalt concrete gives it strength and rigidity. But for the grounds of the sites, this is not so important. Here you can use material type B with a low content of crushed stone. Sand varieties are also suitable: type G (with crushing screening) or D (on natural sand). - Grade

Landscaping jobs do not require high quality asphalt. In order to save money, you can take brand II or even III.

Thus, dense or porous asphalt mix type C, D or D grades II-III will be the optimal choice. These options are the best value for money.

Construction of children's and sports grounds is different from the construction of roads and sidewalks. We will elaborate on these nuances in the next section.

Peculiarities of asphalting the foundations of playgrounds and sports grounds

Asphalt laying is a universal procedure.

It consists of the following steps:

- Preparing the gravel and sand base

- Impregnation of crushed stone with bitumen emulsion

- Paving and screeding of asphalt mix

- Asphalt compaction

We will not analyze them in detail.

If you are looking for detailed step-by-step instructions, check out the following articles:

- Hot Asphalt Technology

- Asphalt cutting technology

However, creating bases for platforms has its own nuances. They are due to the fact that the finish coating will subsequently be laid on the asphalt.

When carrying out work, a number of rules must be observed:

- On a small site, asphalt is laid with a slope of 0.5-1% on the short side. This is done so that puddles do not stagnate between the top coating and the base. After all, asphalt itself does not have drainage properties, and water will not leave through it

- For the reason described above, for large venues and stadiums (from 1000 m2) it is mandatory to equip drainage

- Asphalt is laid in one layer 6-8 cm thick or two - 3-4 cm each. In the second case, each layer is compacted separately

- The surface of the asphalt concrete layer should be as even as possible.

Depressions deeper than 5 mm are not allowed

Depressions deeper than 5 mm are not allowed - The quality of laying is checked using a rail or the “old-fashioned” way: the cooled asphalt is watered from a hose and checked to see if there are puddles left on it

- If it is necessary to locally level the asphalt surface, for this purpose sand ABS is used, laid in a thin layer (no more than 10-20 mm). Do not use cement mixtures for this - they will not reliably adhere to the base

If you do not have tools and equipment on your farm that will ensure the required quality of laying, then it is better to entrust the work to specialists. After all, modern playground surfaces are not cheap. And if you lay them on a poorly prepared base, it will be like throwing money away.

Next, we will talk in more detail about what can be put on the paved area for games and sports.

Soft coatings on asphalt for children's and sports grounds

In accordance with GOST R 52169-2012 and GOST R 55677-2013, coatings for children's playgrounds and sports grounds must be shock-absorbing. After all, a child, when falling even from a small height onto a hard surface, can be severely hurt, or even break something.

After all, a child, when falling even from a small height onto a hard surface, can be severely hurt, or even break something.

To reduce injuries, use:

- Rubber tiles

These are glued to a clean and dry substrate with polyurethane adhesive. Tile coverings are easy to repair: for this, you just need to dismantle and replace the damaged areas. - Modular flooring

It differs from tiles in that it does not stick to the substrate. Instead, the elements are fastened to each other by means of side locks. Due to this, the modules are very easy to install and repair - you can handle it yourself, even if you are doing this job for the first time. And the joints are more dense and airtight - which means that dirt will not accumulate in them. - Roll covering

It is more difficult to lay than tiles or modules: care must be taken that the strips of material do not move and fit as closely as possible to each other, and do not swell when glued. Therefore, it is used less often than other types.

Therefore, it is used less often than other types. - Seamless Rubber Coating

It is a viscous mixture of crumb rubber with polyurethane adhesive. Such a composition can be bought ready-made or mixed at the place of work. When laying it, you need to carefully monitor the evenness of the layer. The advantages of a seamless coating are the complete absence of joints into which dirt can accumulate, as well as the ability to equip a site of any shape and give it any design. - Artificial Grass

This is a more specialized type of turf used for football and tennis courts. Between the blades of such a lawn, dirt and debris can accumulate, which will be difficult to clean out. So it is impractical to take it for children's playgrounds.

The choice of a particular type depends on the goals and budget of the customer. For example, for a small playground it is convenient to use a modular coating, thereby saving on laying. Seamless coatings are good for sports fields: if you take a mixture of several colors, you can immediately make markings from them.

Seamless coatings are good for sports fields: if you take a mixture of several colors, you can immediately make markings from them.

Substrate must be prepared before laying the finish coat:

- Freshly laid asphalt must be allowed to settle for 3-14 days, this is the period during which volatile compounds are released from the material. You can track it by the disappearance of the characteristic bituminous smell. At the same time, the modular coating can be mounted earlier than the glued ones.

- Game and sports structures (slides, swings, wall bars and others) are mounted on the base before laying the rubber coating.

- Before applying the adhesive, the substrate must be degreased. To do this, use special cleaning products (it is important that they do not corrode the asphalt itself - that is, gasoline-based compounds will not work here), which are then washed off with a stream of water from a hose. At the same time, the surface is cleaned of dust, dirt and debris.

If desired and with minimal experience, you can do it all yourself.

So, we have analyzed in detail the intricacies of using asphalt as a base for children's and sports grounds. In the next section, we will talk about when this material is used as a top coat.

Asphalt for sports fields

Asphalt is potentially hazardous. It is very hard, and if you fall on it, you can get serious injuries - up to fractures. Current standards (GOST R 52169-2012, GOST R 55677-2013) do not allow the use of this material to cover playgrounds intended for children.

However, this practice is still common in cities. According to Rossiyskaya Gazeta, back in 2019, 10% of Russian playgrounds were built in violation of standards – this includes the use of asphalt.

In some cases, the case even goes to court. So, in 2017, a resident of the Kemerovo region filed a lawsuit against the management company after her little daughter fell off the Swedish wall onto hard asphalt and suffered a spinal fracture. The court took the side of the injured girl and awarded her compensation.

The court took the side of the injured girl and awarded her compensation.

In this regard, we categorically do not recommend rolling playgrounds into asphalt. If you have a limited budget for landscaping and don't have enough money for expensive rubber pavement, you can replace it with budget alternatives - for example, backfilling on a dirt base. We will discuss this in more detail in the final section of the article.

However, the requirements may be less stringent in other cases.

In particular, a sports field may have a hard surface if:

- It is not intended for children

- It does not have equipment from which it is possible to slip and fall (for example, if it is a regular stadium or a running track)

- Protection zones around sports equipment

Under these conditions, asphalt can be the best option.

It has the following advantages:

- Smooth and stable surface that does not wash out by rain and does not sink

- Quick installation

- Relatively cheap

- Free from dirt and dust

- No puddles (if the minimum slope was observed during laying)

- Cover can be easily cleaned from debris

- In the future, asphalt can be used as a base for rubber, thereby bringing it to full compliance with safety requirements

Let's summarize.

Asphalt by itself is not suitable for playgrounds. And for sports complexes, this is not the best option. However, it is quite budgetary and much more convenient than bare earth (which is washed out and dirty) or sanding (dusty). As an interim measure, asphalt concrete is suitable for running stadiums and tracks, indoor outdoor exercise equipment for adults and other areas where there is no high probability of falls and injuries.

We will talk about which types of material are best suited for these purposes below.

How to choose asphalt for covering a sports ground

As in the case of asphalt bases, there is no strict regulation by GOSTs and SNiPs. When choosing a material, they rely primarily on common sense and existing building practice.

The following criteria are taken into account:

- Roughness

Preference is given to asphalts with a smooth surface, on which there is no risk of seriously peeling the skin when falling. These are primarily mixtures of type D (on natural sand) or G (on sand with the addition of screenings). In extreme cases, you can take type B with a small proportion of coarse aggregate (but it is better that it be gravel, not crushed stone).

These are primarily mixtures of type D (on natural sand) or G (on sand with the addition of screenings). In extreme cases, you can take type B with a small proportion of coarse aggregate (but it is better that it be gravel, not crushed stone). - Paving method

Traditional hot asphalt is the best choice in terms of price and quality. We do not recommend using asphalt cutting for such work, because it is not carried out purposefully, and its quality indicators are not controlled. The properties of the coating from it will be unpredictable. It is also impractical to take cold asphalt, because when ordering large quantities it will be very expensive. - Porosity

The higher the content of air voids in the thickness of the coating, the faster it is destroyed by water and ice. The value of porosity in the coating of outdoor areas should not exceed 10%. According to this criterion, high-density, dense and porous mixtures are suitable.

- Brand

The loads on the sports ground are negligible compared to the road surface. For such work, the highest quality material is not needed - you can get by with grades II or III. - Radioactivity

This value for asphalt for sports fields should not exceed 370 Bq/kg. If the material is certified and the raw material for the mixture is not extracted from contaminated deposits, then exceeding the norm is unlikely.

As you can see, when ordering asphalt for covering a sports field, you can safely save money and get cheaper material. The best choice would be hot sand mix type D grade II or III.

In the next section, we will talk more about how you can reduce the risk of injury on sports facilities with such a surface.

How to reduce the injury risk of asphalt

Do you want to equip a sports field in your yard and use an already asphalted area for this? Or does your child's school have physical education classes in an old paved stadium? Or for any other reason, the question of how you can make such a site safer for sports is relevant for you? Then this section is for you.

We note right away that covering asphalt concrete with a soft rubber coating is too expensive. But if you are not constrained in funds, there is no better option. If this option is not for you, you can use more budget solutions.

These include:

- Rubber around sports equipment

If you can't afford to cover the entire area with crumb rubber, you may still be able to set up local protection zones. The area of such areas (“landing zones”) is calculated according to GOST R 52169-2012. Recommended dimensions - at least 1.5-2 m from each side of the equipment (Swedish wall, crossbar, etc.). It is convenient to equip the protective coating in these areas from tiles or modules. - Construction of sand pits around sports equipment

This method is similar in principle to the previous one, only rubber crumb is replaced by cheap sand filling. You will need a cutter for cutting the asphalt layer and a shovel for digging a hole 20-30 cm deep. The sand will need to be poured in layers of 10-15 cm, sequentially ramming. The junction between sand and asphalt can be additionally protected with rubber pads. The disadvantage of this method is that if in the future you want to equip the finish coating, the old asphalt will have to be removed and laid again.

The sand will need to be poured in layers of 10-15 cm, sequentially ramming. The junction between sand and asphalt can be additionally protected with rubber pads. The disadvantage of this method is that if in the future you want to equip the finish coating, the old asphalt will have to be removed and laid again. - Asphalt coating with rubber paint

These are thick and plastic compounds, similar in consistency to mastic. When hardened, they form a smooth and elastic layer. The paint does not have shock-absorbing properties and cannot replace the impact-absorbing coating. But it makes the asphalt less rough, which means it reduces the risk of peeling the skin when falling. This option is suitable for treadmills and stadiums.

Now you know how to make a safer playground on a hard surface. In the final section of the article, we will talk in more detail about how asphalt can be completely replaced in this kind of work.

Alternatives to asphalting children's and sports grounds

A play or exercise area does not necessarily need a rigid base - especially if it is a small area in the yard of a private or apartment building.

In these cases it is worth considering the following options:

- Compacted soil

The cheapest option is to install play and sports equipment directly on the ground. But in rainy weather, slush and mud will stand on such a site, which the children will carry home on their shoes. - Sand

This is the traditional version. For this task, medium to coarse-grained river sand (it is important that it is certified) is best suited. The coating from it turns out to be soft and safe, and due to its excellent draining properties, it dries quickly after rain. But sand gets into shoes, clothes and hair, and quickly spreads off the site. Periodically, it will have to be added, and once a year - completely replaced in accordance with sanitary requirements. - Crushed stone screening

This is an artificial material similar to sand, which is obtained by crushing rocks into crushed stone. It contains grains of different sizes: from dust to small pebbles with a diameter of up to 5-10 mm. Screenings can be used as budget dumping in those regions where there is no "own" good quality sand. But when ordering, you need to emphasize that you need a homogeneous material with a low content of dust and stones - preferably sieved.

It contains grains of different sizes: from dust to small pebbles with a diameter of up to 5-10 mm. Screenings can be used as budget dumping in those regions where there is no "own" good quality sand. But when ordering, you need to emphasize that you need a homogeneous material with a low content of dust and stones - preferably sieved. - Dresva

This is a type of soil formed as a result of the weathering of rocks. Outwardly, it looks like sand with unrounded grains 2-10 mm in size. You should not be afraid of these grains - they are soft and easily broken in your hands.

Grass is cheaper than sand and screenings. But there is no separate GOST for such material, and its quality varies greatly from deposit to deposit. At one supplier it will look like ordinary coarse sand, while at another it may contain a lot of stones or dust. Therefore, when ordering, specify the quality characteristics of this material. - Wood shavings, sawdust, decorative bark

This filling has good drainage properties and is environmentally friendly - provided that the raw material has not been treated with chemicals. But since we are talking about organic material, after some time it will begin to rot and decompose. In addition, wood can be affected by fungus. This is a good option for arranging a temporary site in a summer cottage, but in the long term it is better to consider other types of dumping.

But since we are talking about organic material, after some time it will begin to rot and decompose. In addition, wood can be affected by fungus. This is a good option for arranging a temporary site in a summer cottage, but in the long term it is better to consider other types of dumping. - Plastic tiles or modules

They have a lattice structure, due to which the coating allows water to pass through, while protecting against dragging dirt around the area. They can also be laid directly on the ground or lawn without special preparation of the base. The advantage of plastic is that it is easy to wash and clean. But, unlike rubber and loose fills, it does not have shock-absorbing properties. In addition, the material does not tolerate frost well - it will have to be dismantled for the winter. - Natural or artificial turf

This is a durable and safe surface that looks good in any area. But for a playground, this is not the best choice. Real grass stains clothes a lot and requires regular maintenance. Artificial turf does not have these disadvantages, but its arrangement is more expensive.

Real grass stains clothes a lot and requires regular maintenance. Artificial turf does not have these disadvantages, but its arrangement is more expensive.

To summarize.

Asphalt is in great demand not only in road construction, but also in landscaping. In particular, it is used in the creation of children's and sports grounds, stadiums, treadmills, courts. In these cases, the material can be used as a base under a rubber coating or as a finishing top coat. However, the latter option is prohibited for playgrounds and is not recommended for sports facilities.

When arranging sites, preference is given to fine-grained (type B) or sandy (types D and D) asphalt concrete mixtures of grades II-III. They have sufficient strength and durability, but at the same time they are relatively cheap. In asphalting such areas there are some nuances that differ from laying asphalt on roads and sidewalks.

As an alternative to hard surfacing, you can consider backfilling with loose material (sand, screenings, grit, shavings), turfing or protective plastic tiles and modules.

If you are interested in other uses for asphalt, please see our related articles:

- Asphalt application

- Landscaping asphalt

- Asphalt for paths and sidewalks

- Parking Asphalt

- Asphalt for roadworks

- Asphalt for road construction

- Asphalt for patching

- Asphalt road construction cost

- Construction asphalt

- Pavement asphalt

- Do-it-yourself asphalt pavement device

- Roof asphalt

- Floor asphalt

- Asphalt cutting technology

- Cold Asphalt Technology

- Asphalt patching technology

- Hot asphalt paving

If you want to learn more about the types of asphalt, we recommend reading the following pages:

- Types of asphalt concrete (asphalt)

How and what asphalt is made of, read here:

If you want to read in detail about the properties of asphalt concrete, we recommend the following pages:

- Characteristics and properties of asphalt concrete

- Water-physical properties of asphalt concrete

- Water permeability of asphalt concrete

- Water resistance of asphalt concrete

- Asphalt swelling

- Water saturation of asphalt concrete

- Asphalt Hazard Class

- Mechanical properties of asphalt concrete

- Deformability of asphalt concrete

- Asphalt rutting

- Asphalt creep

- Strength of asphalt concrete

- Shear resistance of asphalt concrete

- General physical properties of asphalt concrete

- Density and mass of asphalt concrete

- Porosity of asphalt concrete

- Radioactivity of asphalt concrete

- Thermal properties of asphalt concrete

- Thermal expansion of asphalt

- Heat capacity of asphalt concrete

- Thermal conductivity of asphalt concrete

- Technological characteristics and properties of asphalt concrete

- Asphalt Mix Uniformity

- Segregation (separability) of asphalt concrete

- Workability (mobility) of asphalt mix

- Compaction (formability) of asphalt concrete

- Asphalt compaction

- Chemical properties of asphalt concrete

- Performance properties of asphalt concrete

- Combustibility of asphalt concrete

- Wear resistance of asphalt concrete

- Frost resistance of asphalt concrete

- Service life of asphalt pavement

- Crack resistance of asphalt concrete

- How to fix cracks in asphalt

- Asphalt pavement roughness

You can purchase the following types of asphalt from Dirt Trucks:

We also have asphalt cutting (crushed asphalt) for sale.

If you want to buy asphalt of a specific fraction:

- Coarse asphalt

- Fine asphalt

If you want to buy hot asphalt, pay attention to the following varieties:

- Hot Coarse Asphalt

- Hot fine asphalt

We also have cold asphalt for sale:

Children's health camp "Star"

Address: Bessonovsky district

Phone: 8 (8412) 61-11-20, 61-11-19

Location: Penza region, Bessonovsky district, Svetlopolyanskoe farm.

Living and living conditions: Children's health camp "Zvyozdochka" of the municipal educational institution of additional education for children "Children's Health and Education Center" in Zarechny stationary, year-round. It is located 40 km from Penza, next to the river. Vyad. The territory of the camp covers an area of 10 hectares, surrounded by coniferous forest.

On the territory are located:

- 3 bedroom buildings

- administrative and medical building

- canteen and assembly hall complex

- sports fields

- shower room

- outbuildings.

Drinking water fountains are located next to each building.

Meals for children in the camp are five times a day, made in the dining room for 550 seats. Meals are organized in 1 shift. The diet includes juices and fresh fruits.

Available on site:

On the 1st floor of the dining room there is an assembly hall for 200 seats, a meeting room.

On the territory of the camp there is a room in which there are showers for boys and girls (5 cabins each), toilets, a room for washing and ironing linen, a water tank.

The camp has its own boiler house for central heating of the camp and hot water supply to all camp buildings.

The outbuildings of the camp are separated from the main territory by a fence.

Sports and recreation facilities:

- Asphalt basketball court

- Wooden floor basketball court

- 2 volleyball courts

- futsal field

- Sniper field

- large football field

- playground equipped with sports equipment

- Streetball stands and table tennis tables are located near each building.

Socio-cultural objects:

- paved stage: covered stage, three rows of benches for 300 seats arranged in a circle, covered fire pit, 4 flagpoles

- equipped assembly hall for 200 seats

- near each building there are "squad places" for the collection of each squad, information board

- on the 3rd floor of each building there are game rooms, club rooms, a gym, small gyms, video halls.

The entire territory of the camp and living rooms are radio-equipped for local broadcasting.

Equipped: the camp has a complete set of sound and video equipment, a multimedia projector, a screen, TVs, sports equipment, inventory and equipment for clubs and sections.